Newly Built Box Girders in Singapore

Bridge Segmental Adhesive

In box girder bridges, segmental glue is mainly used to connect the segments of prefabricated box girders. Box girders are an important part of bridge structures. Segmental glue can achieve seamless connection between box girder segments, provide reliable bonding force, and improve the overall performance and stability of bridges.

Prefabricated bridge segmental technology is to divide the bridge into several segments, prefabricate it in the factory, and transport it to the bridge site for assembly, and assemble the segments into a bridge by applying prestress. Simply put, "prefabricated segment assembly" is like the "assembly toys" played in childhood, that is, to assemble scattered "building blocks" into a "bridge".

The bridge segmental technology is mainly based on bonding assembly, using bridge segmental glue instead of concrete connection, and loading temporary prestress, and removing the temporary prestress after the glue is completely cured. This segmental method effectively reduces the shrinkage problem of concrete components and is particularly suitable for urban elevated bridges.

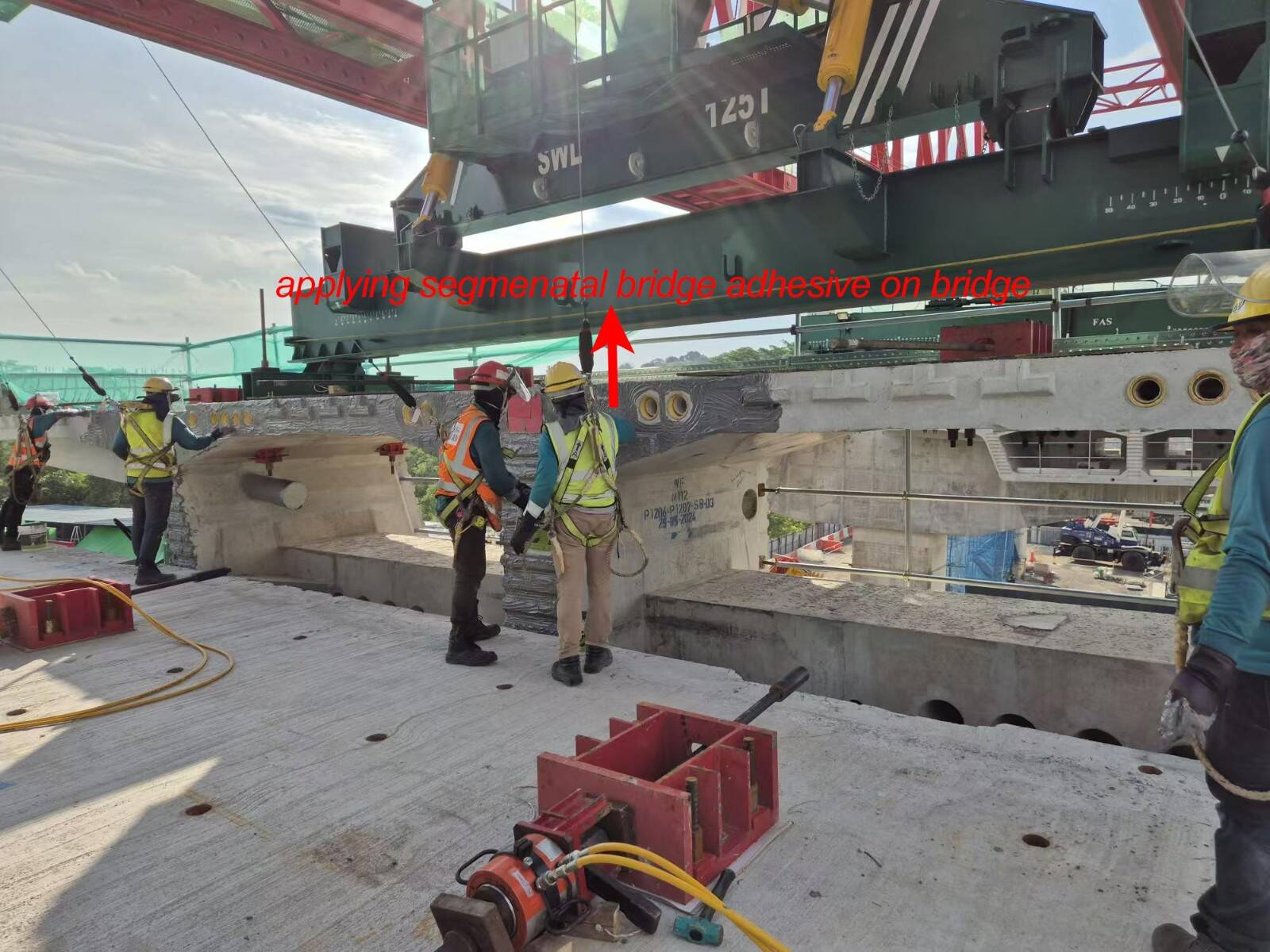

The following project is the segment of a newly built box girder bridge in Singapore

In box girder bridges, segmental glue is mainly used to connect the segments of prefabricated box girders. Box girders are an important part of bridge structures. Segmental glue can achieve seamless connection between box girder segments, provide reliable bonding force, and improve the overall performance and stability of bridges.

It is specifically used in the joints of the web, bottom and top of the box girder to ensure that the connection between the parts is tight and can jointly bear the load of vehicles and pedestrians.

Application characteristics

(1) Lubricating effect: The epoxy resin adhesive is in a viscous state before hardening. When the prefabricated segment is spliced, if the shear key position is slightly deviated, it can slide into position due to the lubricating effect of the epoxy adhesive, which is convenient for the segment beam to be positioned during assembly.

(2) Waterproofing effect: Fill the segment seam, act as a moisture-proof seal to prevent the corrosion of the prestressed cable, and ensure that the beam body can have good anti-seepage performance in the future.

(3) Riveting effect: The epoxy adhesive is filled with pre-pressure to fill the pores on the surface of the cast concrete. After curing, it has high strength and can form a rivet effect, which is conducive to the transmission of stress and increases the resistance of the bridge structure.

Performance advantages

1) High thixotropy, no sagging, no dripping.

2) High strength, high elastic modulus, low creep

3) The glue can be applied for a long time, and the curing is rapid, the strength develops quickly, and does not affect the prestressing tension

4) The colloid has no coarse aggregate, the colloid is fine, the density is small, and the dosage is saved

Good thixotropic structural adhesive has several advantages for reinforcement projects:

1. The structural adhesive has good stability during storage and transportation;

2. Good construction performance, easy to stir, easy to apply, and no dripping;

3. The glue is applied evenly to obtain better bonding effect;

4. Save glue and save engineering costs.