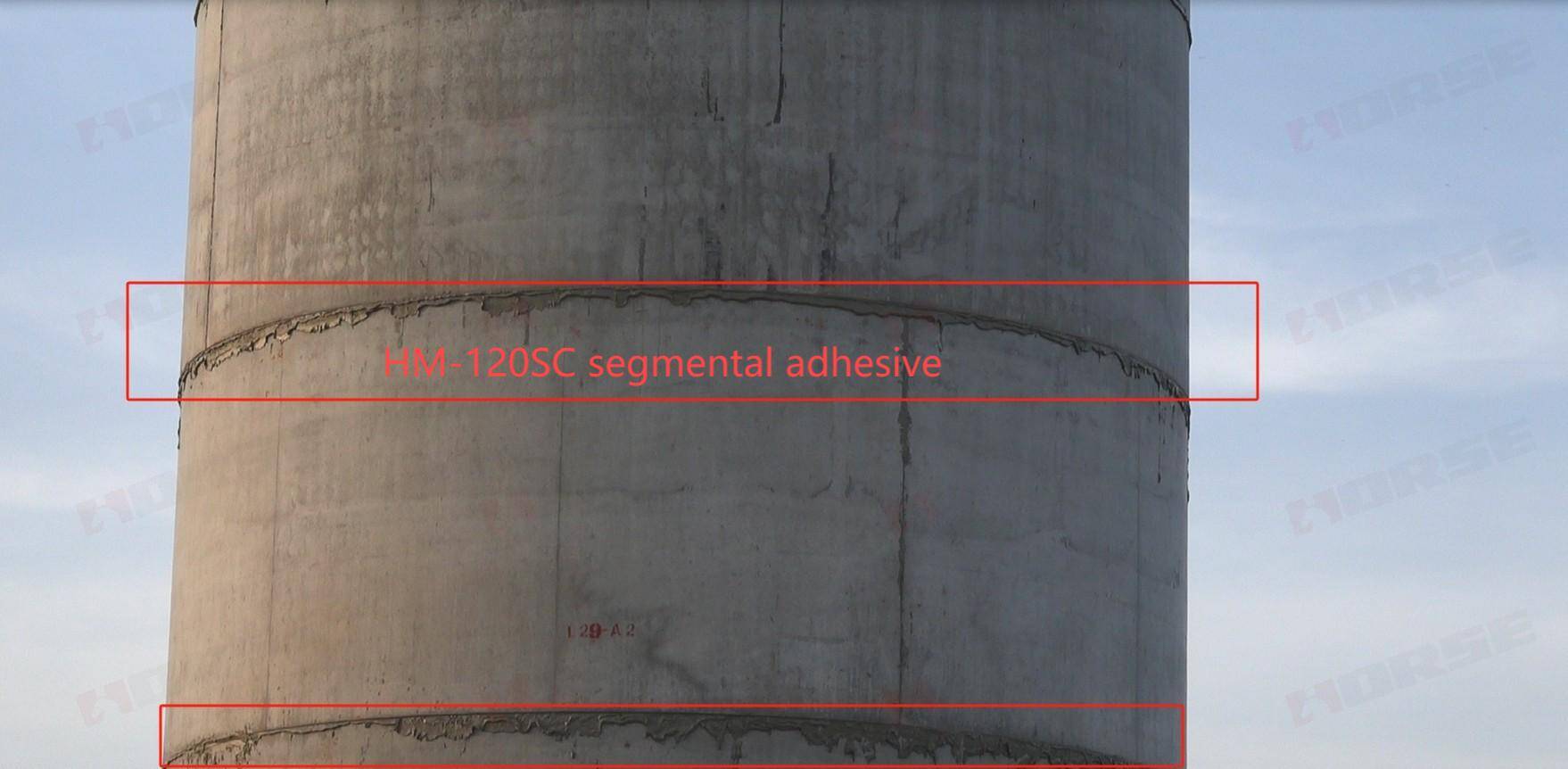

Wind Turbine Concrete Tower Assembly

HM-120SC element bonding adhesives

HM-120SC element bonding adhesives have already been used for effectively to bond precast concrete elements together and provide a rigid bond between elements to transfer load.

To maximize power generation and make the most of the available wind, the decision was made to add some wind turbine concrete towers. The project aimed to not only increase the energy output but also contribute to the local renewable energy portfolio in a sustainable and cost - effective manner.

After careful consideration of various adhesive options in the market, the project team chose HM - 120SC adhesive. The decision was based on its remarkable characteristics. Its high bond strength was a major factor, as the towers needed to endure strong winds and mechanical stresses. The chemical resistance of HM - 120SC was also crucial, given the wind farm's proximity to the sea, which meant exposure to salty and humid air. Additionally, the excellent thermal stability of the adhesive was appealing, considering the large temperature differences between day and night in the area.

Assembly Process

1) Surface Preparation

The surfaces of the concrete sections for the tower were thoroughly cleaned. Any dust, dirt, or loose particles were removed using high - pressure water jets and brushes.

Roughening was carried out to increase the surface area and improve adhesion. This was done using grinding machines to create a rough texture on the mating surfaces.

After cleaning and roughening, the surfaces were dried completely. Infrared heaters were used to ensure there was no moisture left, as even a small amount of water could affect the adhesive's performance.

2) Adhesive Application

A specialized dispensing machine was used to apply the HM - 120SC adhesive evenly on one of the mating surfaces. The machine was calibrated to ensure the correct amount of adhesive was applied, as per the manufacturer's instructions.

The adhesive was spread in a thin, uniform layer, covering the entire surface that was going to be joined.

3) Tower Section Joining

Once the adhesive was applied, the two concrete sections were carefully brought together using a large - capacity crane. The alignment was checked using laser - guided systems to ensure precision.

After the sections were in place, they were clamped tightly using high - strength clamps. The clamps were left in place for the recommended curing time of the adhesive, which was 2 hours at the ambient temperature.

In conclusion, the use of HM - 120SC adhesive in the project has been a resounding success. It has not only ensured the structural integrity of the 160 - meter wind turbine concrete towers but also contributed to the overall success of the wind farm in terms of power generation and cost - effectiveness.