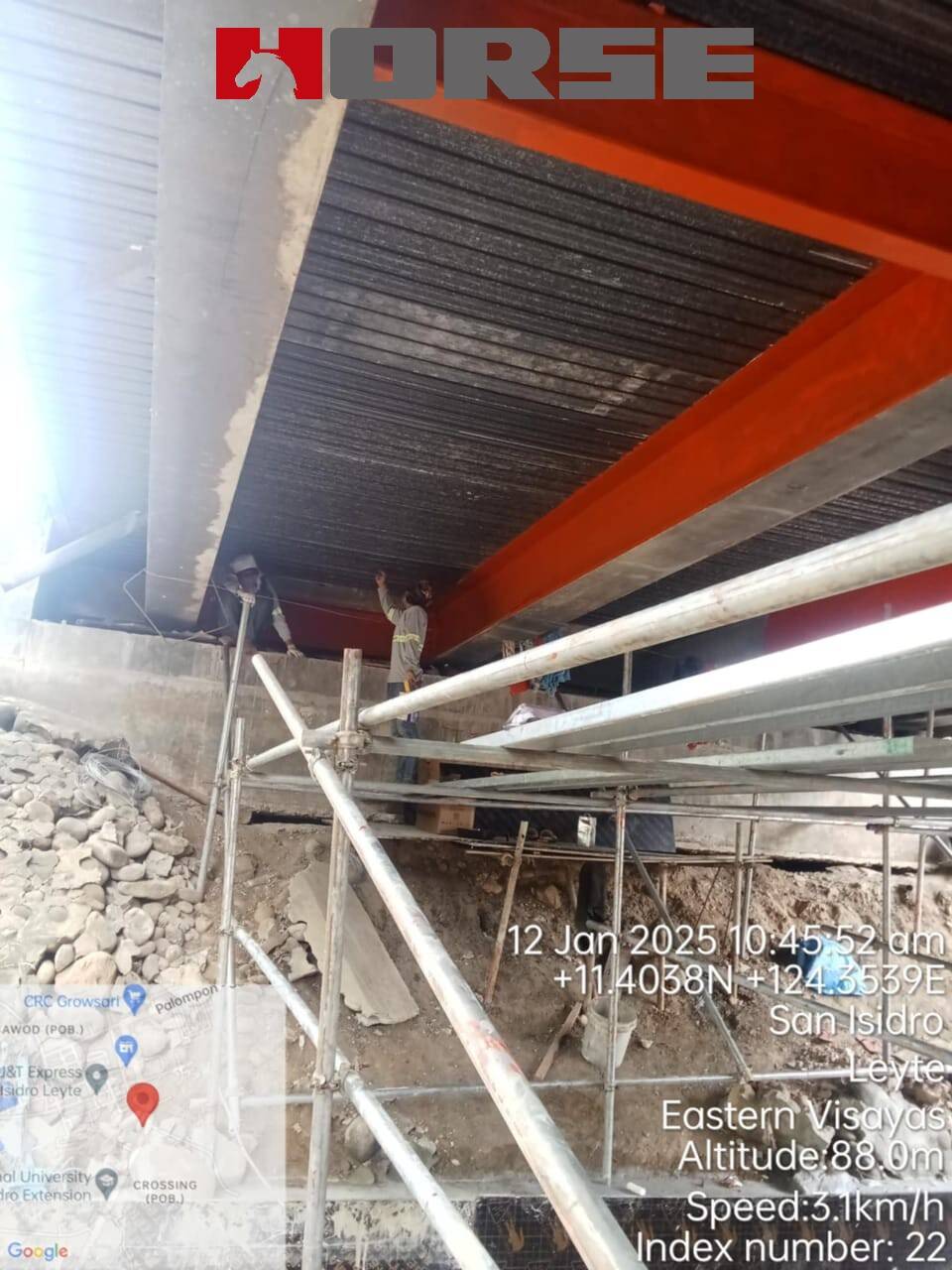

Strengthening Concrete Bridge in Philippines

using CFRP Laminates

In the Philippines, with its rapidly developing infrastructure and a significant number of aging concrete bridges, the need for effective and efficient bridge strengthening techniques has become increasingly crucial.

In the Philippines, with its rapidly developing infrastructure and a significant number of aging concrete bridges, the need for effective and efficient bridge strengthening techniques has become increasingly crucial. Concrete bridges in the country are often subjected to harsh environmental conditions, including typhoons, heavy rainfall, and high humidity, which accelerate the degradation process. Additionally, the growing traffic volume, especially the increasing presence of heavy trucks, puts extra stress on these structures. Carbon Fiber Reinforced Polymer (CFRP) laminates have emerged as a viable solution for strengthening concrete bridge sections due to their numerous advantages such as high strength - to - weight ratio, corrosion resistance, and ease of installation. This case study focuses on a particular concrete bridge in the Philippines that was strengthened using CFRP laminates, detailing the entire process from problem identification to the final outcome.

It is a reinforced concrete slab - on - girder structure, with the concrete girders supporting a reinforced concrete deck slab. Over the years, due to continuous exposure to the elements and the increasing traffic load, the bridge started to show signs of distress. Visual inspections revealed numerous cracks on the concrete deck slabs. Core samples were taken from the concrete, and the results indicated a reduction in the concrete's compressive strength. The corrosion of the steel reinforcement bars was also detected in some areas, which was a major concern as it could lead to a significant loss of structural integrity.

After a comprehensive assessment of various strengthening options, including traditional methods such as steel jacketing and external prestressing, CFRP laminates were chosen as the most suitable solution for this bridge. The high strength - to - weight ratio of CFRP laminates was a significant advantage. Since the bridge was already experiencing issues related to its structural capacity, adding excessive weight from traditional strengthening methods could exacerbate the problem. The CFRP laminates, being lightweight, could be installed without significantly increasing the dead load of the bridge. Their excellent corrosion resistance was also highly beneficial considering the harsh coastal environment of the bridge's location, where the concrete was constantly exposed to salt - laden air from the nearby sea. Moreover, the installation process of CFRP laminates is relatively quick and less invasive compared to other methods. This was crucial as minimizing traffic disruption during the strengthening works was a top priority. The bridge is located on a busy thoroughfare, and any long - term closure would have a significant impact on the local economy and daily life of the residents.

The analysis took into account the existing condition of the bridge, including the location and severity of cracks, the reduced concrete strength, and the corrosion of reinforcement bars. The goal was to determine the required amount and configuration of CFRP laminates to restore the bridge's structural integrity and ensure its ability to withstand the current and future traffic loads. The software simulated different loading scenarios, such as static and dynamic loads from vehicles, as well as environmental loads like wind and earthquake forces. The areas with the widest cracks and the lowest concrete strength were identified as the critical sections that needed to be reinforced with CFRP laminates.

The CFRP laminates selected for the project had a thickness of 1.2 mm and a width of 50mm.

After the completion of the strengthening works, long - term monitoring of the bridge was established. In addition, regular visual inspections of the bridge were carried out to check for any signs of new cracks, delamination of the CFRP laminates, or other visible defects. The monitoring results were used to evaluate the effectiveness of the strengthening work and to ensure the long - term performance and safety of the bridge.

The strengthening of the bridge using CFRP laminates has significantly improved its structural performance. Follow - up structural analysis and load testing after the completion of the project showed that the bridge's load - carrying capacity had increased by 45%. The cracks on the concrete deck slab and girders that were previously a major concern have been effectively arrested.

The corrosion - resistant property of the CFRP laminates has enhanced the durability of the bridge. In the harsh coastal environment of the Philippines, where traditional steel - based strengthening methods would be prone to corrosion, the CFRP laminates have provided a long - lasting solution. The epoxy resin matrix of the CFRP laminates not only bonds well with the concrete but also acts as a protective barrier against the salt - laden air and moisture, preventing further corrosion of the underlying steel reinforcement bars. This has significantly extended the service life of the bridge, reducing the need for frequent maintenance and repair in the future.

In terms of cost - effectiveness, the use of CFRP laminates for strengthening the bridge has proven to be a favorable option. Although the initial cost of the CFRP materials and the installation process may be relatively higher compared to some traditional methods, the long - term savings in maintenance and repair costs are substantial. The reduced need for frequent inspections and repairs due to the improved durability of the bridge, as well as the minimized traffic disruption during the strengthening works, have resulted in overall cost savings. Moreover, the extended service life of the bridge means that the need for costly bridge replacement can be postponed, providing significant economic benefits to the local government and the community.