Hybrid Wind Turbine Tower Concrete Segmental Construction

HM-120SC

Select language

HM-120SC

The wind hybrid concrete and steel towers, with a hub height of 168 metres. The tower is constructed using convex concrete segments, each up to 20 metres long. These segments are precast locally since the summer of 2025.

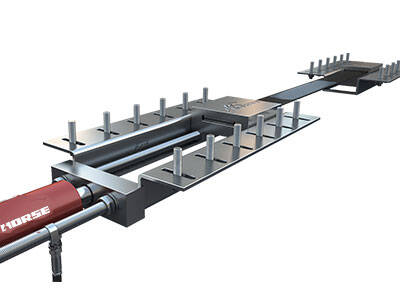

The wind hybrid concrete and steel towers, with a hub height of 168 metres. The tower is constructed using convex concrete segments, each up to 20 metres long. These segments are precast locally since the summer of 2025. On-site, the concrete segments are first assembled and braced. Once the concrete base structure is in place, the steel sections, nacelle, and rotor are installed on top. This modular approach of using precast concrete segments allows for efficient construction and better quality control, as each segment can be manufactured with precision in a controlled factory environment.

Advantages of Concrete Segmental Construction

Enhanced Structural Integrity: Concrete provides a firm and stable base for the tower. For a tall structure like the 168-metre towers, the mass and strength of concrete help in reducing dynamic loads on the entire structure. This, in turn, enables the use of lighter and more cost-effective components in the upper steel sections and the turbine itself.

Efficient Transportation and Assembly: The individual concrete segments are designed to be transportable, even in complex terrains. Their modular nature allows for easier handling during transportation to the wind farm site. Once on-site, the segments can be assembled relatively quickly, reducing the overall construction time compared to some other tower construction methods.

Website Map | Corporate | Contact | Privacy