Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

carbon fiber thickness

Carbon fiber reinforcement generally includes carbon fiber fabric reinforcement, carbon fiber plate reinforcement and carbon fiber mesh reinforcement. They will involve force calculations when strengthening the structure, which will inevitably use the thickness of the carbon fiber composite material, so how is the thickness of the carbon fiber material determined? Now Horse Construction introduces to everyone:

As everyone knows, carbon fiber cloth is divided into 300g and 200g according to the weight, and their thickness is 0.167mm and 0.111mm respectively. How did this thickness come from? Is it measured by calipers? Of course not, this thickness is calculated.

We know that the density of carbon fiber is 1.8g/cm³, and the mass of 300g carbon fiber cloth per square meter is 300g. According to V=M/ρ, V=300g/1.8g/cm³=167cm³, then the thickness d=V/S=167cm³ /1㎡=0.167mm. This calculation is actually the average thickness of the carbon fiber, not its actual thickness. The thickness of 200g carbon cloth and carbon fiber mesh is also calculated based on this. The carbon plate is different. The carbon plate is pultruded in a customized mold, and its thickness is determined, and when talking about the specifications of the carbon plate, the thickness is also directly mentioned.

The thickness of the carbon plate is the actual thickness. There is no doubt about this. Why do carbon cloth and carbon fiber mesh express its thickness in this way? During the weaving process of the main carbon cloth and mesh, there will be some gaps. If the calculation is carried out according to the actual thickness of the carbon cloth and the grid, the gap must be subtracted in the force calculation, which will bring great trouble to the calculation.

In fact, the thickness of some aramid fiber cloth and glass fiber cloth are calculated according to this method, and this method does save a lot of trouble for everyone in the calculation.

With the rapid development of my country's economic construction and transportation, a considerable part of the existing buildings caused historical problems due to the low design load standards at that time. Due to the changes in the use of some buildings, it is difficult to meet the requirements of the current standard use, and urgently need to be repaired and reinforced. As an epoch-making reinforcing material, carbon fiber has attracted much attention and attention for its unique advantages such as easy construction, low cost, and good durability.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

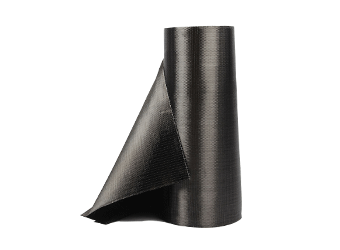

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.