Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Characteristics And Advantages Of Carbon Fiber And Composite Materials

Characteristics And Advantages Of Carbon Fiber And Composite Materials

Overall design ability

We can design materials based on intervention rather than the other way around.

Save costs directly from the project

We only design the materials needed, so based on calculations, it can work in the direction and way necessary for the needs of a particular building. We don't care how many square meters of carbon fiber are sold, but the problem is solved.

High mechanical resistance performance

Other building materials with the same weight and size, or other building materials suitable for buildings, do not have the resistance of composite materials.

Shape and adaptability of shape

With the help of vaults or columns, arches or beams, we can shape the carbon fiber reinforced parts with extremely high precision according to the shape of the supporting parts to be applied. The directionality of the steel bars ensures a direct response to the source of stress on the structural elements.

Durable

The carbon fiber composite material system guarantees an almost unlimited service life. It will not undergo chemical changes over time (such as concrete), and will not be affected by oxidation processes (such as construction steel). It will not be corroded by the atmospheric medium (acid rain), and it is impossible to be attacked in the saline environment (seaside resort). In extreme cases, if a suitable insulation system is used for protection, this is actually impeccable.

Portability of steel bars applied to the structure

The weight will not increase, nor will it increase the load on the steel structure. Even the multi-layer carbon reinforcement material is no more than 1/3 mm thick.

Very low invasiveness

"Surgical" interventions can be performed on existing buildings without the need to clean up civilian houses or completely shut down public facilities. If it is foreseeable, the structure can be plastered or hung, so the intervention is actually invisible.

Extremely easy construction

Ordinary carbon fiber tape weighs about 300 grams per square meter! The resin is transported in a 30 kg rail. . There is no need to store bulky materials, which reduces the obstacles for other operators on the construction site.

Reduce installation time and increase speed

A large amount of reinforcement can be carried out within a few hours, thereby reducing the inconvenience of the end user and shortening the delivery time of the enterprise.

Possibility to check the quality of the applied reinforcement

Using modern and effective systems, such as infrared thermal imaging or ultrasonic testing, factory managers or customers can directly verify the perfect execution of structural reinforcement.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

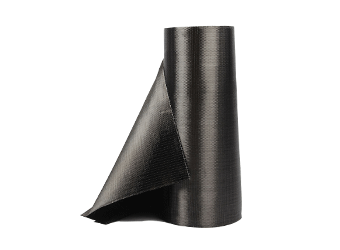

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

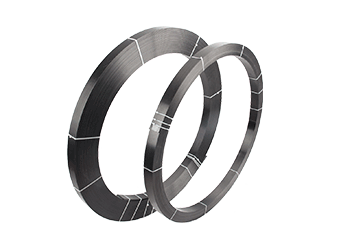

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.