Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Reinforcement Technology For Prestressed Carbon Fiber Strip

Carbon fiber strip selection

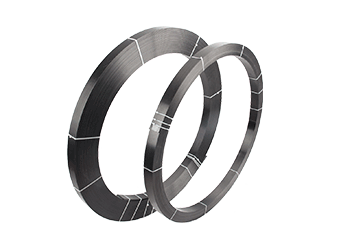

Carbon fiber strip selection The choice of carbon fiber strip is the key to technology. Combining its material properties and mechanical properties, select the strip with the best bridge reinforcement performance for construction. The carbon fiber strip itself is characterized by light weight and high strength. Conventional sizes can be divided into two types: width 50mm and 100mm, and thickness 1.2mm and 1.4mm. That is, the four specifications are: 50mm×12mm, 50mm×14mm, 100mm×12mm, 100mm×14mm. The selection of the actual construction strip should be determined according to the tensile force required by the carbon fiber strip under the specific situation and the manufacturer's guidance.

Tension method of carbon fiber strip

The method of tensioning the prestressed carbon fiber strip is the key to whether the reinforcement of this technology can achieve the effect. At present, the prestressing method can be divided into three types, namely the inverted arch method, the pre-tension method and the post-tension method.

Inverted arch

The basic theory of the anti-arch method in its implementation is to use a jack to apply anti-arch force to the old concrete bridge body, so that the concrete beam body is arched upward. Then use CFRP to paste on the concrete beam. After the paste strength reaches the standard, the external load will be unloaded. During the whole unloading process, the corresponding prestress must be applied to the CERP. In the current construction process, this direct method of pasting still has a certain effect in the secondary prestressing force. However, due to the economy of the inverted arch method and the harshness of the construction environment, it is necessary to use large-tonnage jacks to realize the lifting of concrete beams. The constant load of the concrete prestressed beam body is relatively large and the secondary prestress obtained for the prestressed concrete beam body is relatively small. The construction process is not easy to control, and the magnitude of the applied prestress is difficult to control. Therefore, this method is rarely used in actual construction.

Pretension

In the carbon fiber strip reinforcement of the bridge, the bridge bottom plate is first processed by a certain procedure, and then the strip is stretched to the previously set stress level by using the externally set tensioning equipment. Then apply the required adhesive on the bottom of the bridge and other places to keep the strip and the bottom of the beam in full contact. A high degree of adhesion is achieved under the action of external pressure, and then the end plates will be sheared and the relevant components will be given a certain prestress.

Post-tensioning

In the use of post-tensioning method for reinforcement construction, the prestress of the carbon fiber strip must be post-tensioned with a complete anchor, and the anchor will permanently act on the post-tensioned beam. And make the prestress and the beam body bear the force as a whole to form a permanent joint force reinforcement member, so as to realize the application of the post-tensioning method.

Application Scope of Bonded Prestressed Reinforcement System

With the development of technology in recent years, there are two ways to strengthen the external prestress of concrete prestressed beams, namely the unbonded body method and the bonded body method. This is also the preferred method commonly used to reinforce bridges with carbon fiber strips. . The non-bonded body method is to fix the prestressed carbon fiber strip inside the concrete beam body, and apply a tensile force to the concrete beam body after it reaches a certain strength. Using this technology, the biggest follow-up core technology is: the support and protection of the carbon fiber strip and the stability and adhesion of the reinforcement position. Therefore, this construction technology is widely used in the reinforcement of small and medium-sized reinforced concrete prestressed T beams. For the bonded body method, the post-tensioning method must use steel strands or fine-rolled rebars to apply prestress, and after the tensioning, a compressive slurry that meets the tensile strength must be used for grouting, so as to achieve the beam body and The overall force of the tensile force of the steel strand. This kind of reinforcement method with bonded body has stable effect and is a commonly used reinforcement technology. Generally suitable for use in small and medium-sized reinforced concrete prestressed T beams or prestressed small box beams and hollow slabs.

Tension control stress

Reinforcing reinforced concrete beams with prestressed carbon fiber strips can effectively control component deformation, strengthen the stress system of the beam, improve the integrity and lateral force of the beam, significantly reduce the deflection and deformation of the beam, and prevent cracks in the beam. expansion. Prestressed carbon fiber strip reinforcement technology, the main research direction is the application process of tensile force and whether the tensile force is controllable. For this kind of tensioned prestressed plates, the value of the tension control stress directly affects the effect of the beam reinforcement technology. If the control stress applied to the carbon fiber strip is too small, the carbon fiber strip cannot be put into work with full performance, nor can it exert its mechanical properties, and its beam reinforcement effect will not meet the requirements, resulting in the failure of the entire reinforcement process. If the control stress of the carbon fiber strip is too large, the beam body cannot guarantee that the carbon fiber strip has a certain deformation interval when the load is deformed, which makes the carbon fiber strip extremely prone to fracture. Therefore, construction personnel must accurately calculate the range of carbon fiber strip control stress, so that the mechanical properties of carbon fiber strip can be controlled within a reasonable range, so as to avoid failure of reinforcement measures due to the value of control stress, which will cause certain economic and safety problems.

Anchoring method

For the post-tensioning reinforcement technology of prestressed carbon fiber plates, the anchoring method adopted is the key to the success of the entire reinforcement. The quality of the current anchoring system has a great influence on the prestressed carbon fiber strip reinforcement technology. A reasonable and effective anchoring system can better reflect the mechanical properties of the prestressed carbon fiber, thereby making the reinforcement effect more significant. At present, the anchoring methods used in construction technology are slotted and non-slotted. The slotted anchoring method is to cut out a layer of concrete under the concrete beam floor. Generally, the grooved depth of the beam body is 20mm to process the position where the carbon fiber strip is placed. However, the thickness of the bottom plate protection layer of concrete beams is generally 30-50mm thick, so cutting out 20mm concrete will cause a certain degree of damage to the protection layer, leaving part of the bottom plate steel bars exposed, thereby destroying the durability of the beam. The biggest advantage of the non-slotted anchoring method is that it does not need to cause damage to the concrete beam, nor does it need to excavate the beam floor, the construction process is simple, the construction process is better controlled, and the effect is better. Therefore, this method is more widely used in applications.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) strip for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

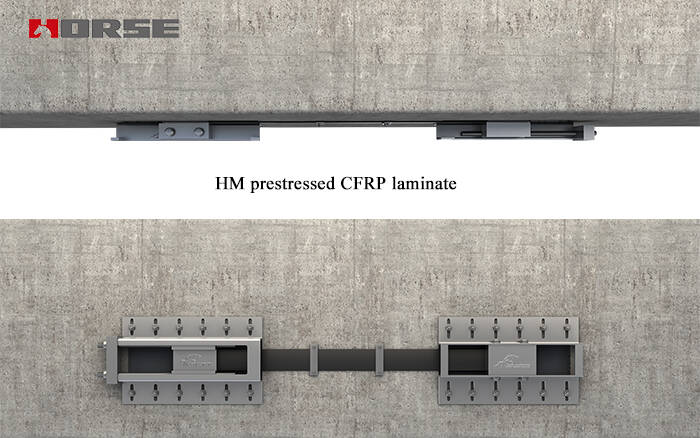

Prestressed carbon fiber reinforced polymer(CFRP) laminate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.