Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Unidirectional Carbon Fiber VS 3K Carbon Fiber

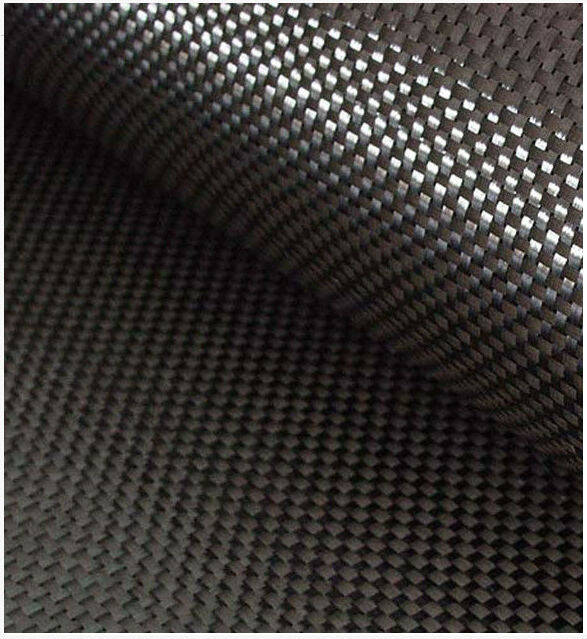

What does the ‘K’ of 3K carbon fiber fabric mean?

According to carbon fiber specifications, carbon fiber reinforced fabric can generally be divided into 1K, 3K, 6K, 12K carbon fiber reinforced fabric and large tow carbon fiber reinforced fabric (such as 15K, 24K, or even 48K). Therefore, the ‘K’ of 3K carbon fiber fabric represents the specification of carbon fiber fabric.

Carbon fiber fabric is woven from bundles of carbon fiber filaments. 1K means that one of the filaments contains 1000 filaments, and 3K means that one bundle contains 3000 carbon fiber filaments.

Generally, the smaller the tow, the better the strength and performance of carbon fiber, and at the same time, the higher the cost.

Unidirectional carbon fiber fabric refers to a carbon fiber fabric with a large number of carbon fiber filaments in one direction (usually the warp direction), and a small amount and usually thin carbon fiber filaments in the other direction, so all the strength of the fabric is in the same direction.

Advantages of unidirectional carbon fiber fabric

1. The construction quality is easy to guarantee

Because the carbon fiber fabric is soft, it guarantees 100% effective adhesion even if it is reinforced on objects with uneven surfaces. If there are air bubbles on the surface of the paste, the air can be easily driven away by injecting the paste with a syringe, but it is difficult to paste the steel plate.

2. Convenient construction

There is no wet work, no large construction equipment, no on-site fixed facilities. The carbon fiber fabric can be cut arbitrarily, the construction is simple, and the construction period is short.

3. Thin thickness and light weight

After pasting, the weight per square meter is less than 1.0kg (including glue weight), and the thickness of a layer of carbon fiber fabric is only 0.111 mm/0.167mm/0.333mm. After repairing, there is basically no increase in weight and external dimensions.

4. Wide application

Bonding carbon fiber fabric for reinforcement and repair can be widely used in various types and shapes of concrete structures without changing the shape of the structure and without affecting the appearance of the structure.

Carbon fiber fabric has excellent physical and mechanical properties, the tensile strength is 7-10 times higher than that of ordinary steel, and the elastic modulus is close to that of steel, which is very suitable for the reinforcement and repair of reinforced concrete.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

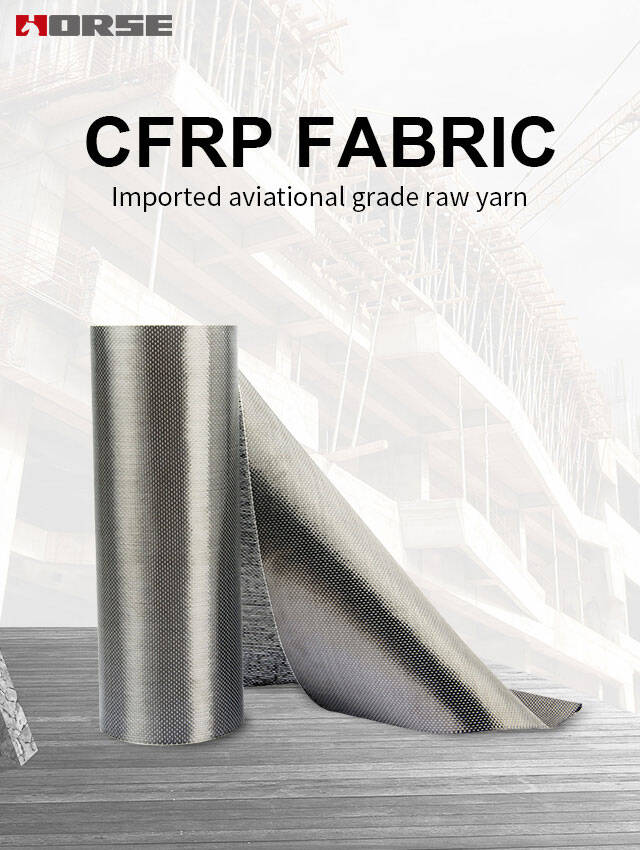

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.