Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Wall Strengthening with UD Carbon Fiber | Horse Construction

When it comes to structural strengthening, carbon fibre are often the preferred choice over traditional steel plates due to their flexibility, versatility and superior strength-to-mass ratio.

If you’re looking to reinforce and strengthen concrete walls then carbon-fibre strengthening may be an option.

The reasons for choosing carbon fiber reinforced walls include the following:

Improving wall strength and stability: The use of carbon fiber can increase the strength and stability of the wall, preventing problems such as cracks, deformation, and tilting.

Reduce construction time and cost: Compared to traditional reinforcement materials such as reinforced concrete or steel plates, carbon fiber reinforcement can complete the work more quickly, reducing construction time and cost.

Wide application range: Carbon fiber can be applied to different types of walls, including concrete, brick walls, gypsum boards, etc. Therefore, it can be applied to various building structures and environmental conditions.

Lightweight design: Carbon fiber is a lightweight material that, compared to traditional reinforcement materials such as reinforced concrete or steel plates, can reduce the increased load and reduce the use of reinforcement materials.

Strong durability: Carbon fiber has good durability and corrosion resistance, can be used under various environmental conditions, and can maintain the strength and stability of walls for a long time.

The process of using carbon fiber for wall reinforcement typically includes the following steps:

Assess the damage situation of the wall: Firstly, it is necessary to evaluate the damage situation of the wall, determine the reinforcement method and required materials.

Preparation work: For the coating, paint, plaster and other materials on the wall surface, it is necessary to remove them thoroughly for subsequent construction.

Treatment of damaged areas: For cracks, holes, depressions, and other areas on the wall, treatment is necessary to facilitate subsequent construction.

Apply epoxy resin: Apply a layer of epoxy resin to the wall for subsequent carbon fiber fixation.

Installation of carbon fiber: Fix the prefabricated carbon fiber board or carbon fiber cloth on the wall in the area coated with epoxy resin.

Apply epoxy resin: Apply another layer of epoxy resin on carbon fiber board or carbon fiber cloth to facilitate the fixation of the carbon fiber material.

Sanding treatment: Wait for the epoxy resin to dry before sanding the fixed part of the carbon fiber to make it flush with the surrounding wall surface.

Painting: Finally, use wall paint to paint the reinforced area and the surrounding wall surface, in order to beautify the entire wall.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

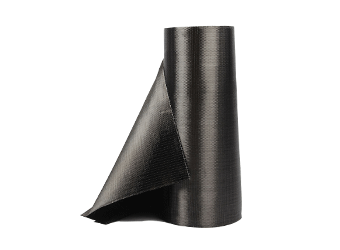

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.