Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

why carbon fiber?

Jetty is the interface between the land mode of transportation and waterways. Because of the suituation, there are a lot of problems on it.

Corrosion: Corrosion is a common issue for jetties, especially those exposed to saltwater environments. Over time, the corrosive nature of water and salt can degrade the structural components of the jetty, such as steel reinforcements or concrete. Corrosion may lead to rusting, cracking, or weakening of the structure, necessitating repairs to restore its integrity.

Erosion: Jetties located in coastal areas may experience erosion due to the action of waves, currents, and tidal forces. The constant movement of water can erode the materials comprising the jetty, particularly if they are not adequately protected. Erosion can result in the loss of soil or sediment around the jetty's foundation or undermine the stability of the structure, requiring repair work to prevent further damage.

Structural Damage: Jetties can sustain structural damage from various sources, including impact from vessels, heavy storms, or natural disasters. Collisions with ships or floating debris can cause significant damage to the jetty's structural elements. Severe storms, such as hurricanes or strong waves, can exert excessive forces on the jetty, leading to cracks, displacements, or even partial collapse. Structural damage typically necessitates immediate repair to ensure the safety and functionality of the jetty.

Wear and Tear: Jetties experience continuous exposure to environmental elements, including water, wind, and temperature fluctuations. Over time, this exposure can result in general wear and tear of the jetty components. For example, the decking, fenders, or mooring equipment may degrade, requiring replacement or repair to maintain the operational efficiency of the jetty.

Age and Lack of Maintenance: Older jetties or those that have not received regular maintenance may require repairs due to aging or neglect. Lack of routine inspections, cleaning, and upkeep can allow minor issues to escalate into more significant problems. Aging infrastructure may exhibit deteriorated materials, weakened structural elements, or outdated design features that demand repair or rehabilitation.

Why a lot of company use carbon fiber for repairing jetty?

Repairs of Jetty and Marine strucutres with HORSE CONSTRUCTION Carbon Fiber Products

Carbon fiber is a good material for jetty corrosion resistance due to several key characteristics:

Corrosion Resistance: Carbon fiber is inherently corrosion-resistant. Unlike metals such as steel or aluminum, carbon fiber does not rust or corrode when exposed to moisture, saltwater, or harsh chemicals typically found in marine environments. This property makes carbon fiber an excellent choice for structures like jetties that are exposed to water and corrosive elements.

High Strength-to-Weight Ratio: Carbon fiber composites are known for their exceptional strength-to-weight ratio. They possess high tensile strength while being significantly lighter than traditional materials like steel or concrete. This strength allows carbon fiber jetties to withstand the forces of waves, tides, and impacts without compromising structural integrity.

Durability and Longevity: Carbon fiber is highly durable and has a long service life. It is resistant to fatigue, meaning it can withstand repeated loading and exposure to environmental conditions without weakening. This durability ensures that carbon fiber jetties can withstand the constant exposure to water, waves, and weather over an extended period.

Low Maintenance Requirements: Carbon fiber structures, including jetties, require minimal maintenance compared to traditional materials. They do not require regular painting or protective coatings to prevent corrosion. Carbon fiber's resistance to environmental degradation reduces the need for frequent inspections and repairs, resulting in cost savings and less disruption to operations.

Design Flexibility: Carbon fiber composites offer a high degree of design flexibility. They can be molded into complex shapes and sizes, allowing for customized jetty designs to suit specific requirements. This flexibility facilitates the integration of additional features like corrosion-resistant coatings or reinforcements in critical areas, further enhancing corrosion resistance and structural performance.

Thermal Stability: Carbon fiber exhibits excellent thermal stability, enabling it to withstand temperature variations and resist degradation due to heat. This characteristic is particularly important in marine environments where jetties may be exposed to high temperatures from the sun or other heat sources.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

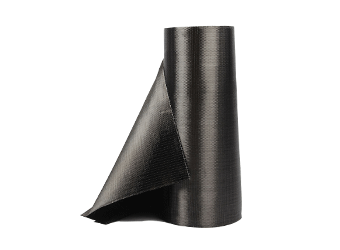

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.