Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Why Do Customers Buying Anchor Adhesive Especially Care About The Tactileness Of Glue?

What is thixotropy?

From the perspective of rheology, thixotropy refers to a rheological phenomenon in which the viscosity of a system changes over time when subjected to shear action (agitation or other mechanical actions). A "touch" is a "change", like "stillness like a virgin, motion like a rabbit". The concept of viscosity originated from Newton's research on simple fluids ("Newtonian fluids"), and later evolved into a definition where the ratio of shear stress to shear rate is defined as the apparent shear viscosity at a certain shear rate, abbreviated as viscosity. At a certain temperature, viscosity is a function of shear rate. Most actual fluids exhibit non Newtonian properties, with shear thinning being more common.

In theory, all shear thinning and recovery phenomena have a temporal nature, but it is only a matter of whether the temporal effect is significant and perceptible. The formation of structures between particles within the colloid results in structural damage during flow and structural recovery upon cessation of flow. However, both structural damage and recovery are not immediately completed and require a certain amount of time. Thixotropy can be regarded as the performance of the conversion process between "gel sol" at constant temperature.

Characterization methods for thixotropy

Thixotropic samples exhibit two typical behavioral characteristics simultaneously: 1) shear thinning; 2) Timeliness. So does high thixotropy refer to a greater degree of shear thinning or a stronger temporal dependence? This starts with the characterization method of thixotropy.

There are usually three methods for characterizing thixotropy: thixotropy index method, thixotropy loop method, and structural damage reconstruction method.

At present, the thixotropy in the adhesive process is mainly characterized by the thixotropy index It. The measurement method for this index is to measure the apparent viscosity of an adhesive using two significantly different shear rates at a specified temperature (usually 23 ° C) η 1 and η 2, and η 1 > η 2, then It= η 1/ η 2. The ratio of the apparent viscosity at low speed to the apparent viscosity at high speed, which means that it measures the approximate shear thinning index and can only generally characterize the degree of shear thinning. The advantage of this method is that the instrument cost is low and it is easy to popularize. The disadvantage is that it can only comprehensively characterize the degree of shear thinning of the sample and cannot characterize its time-dependent behavior.

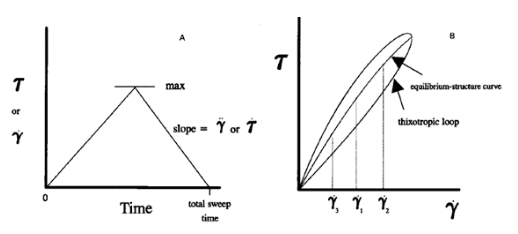

The principle of the thixotropic loop method is that when the shear rate continuously increases from 0 to a constant value, and then gradually decreases from this constant value to 0, the change in stress with the shear rate is measured, and the closed curve of shear stress shear rate is called the thixotropic loop. By changing the values of different times and maximum shear rates, different areas of thixotropic loops can be obtained. The larger the area of the thixotropic ring, the greater the thixotropy, and vice versa. But does it mean that the thixotropy of two samples is the same if their thixotropy ring areas are equal but their contours are different? The answer is clearly no, and this method is gradually becoming outdated.

The structural failure reconstruction method, also known as the three stage thixotropy method (3ITT), has become increasingly popular in recent years. Its evaluation method is to use a three stage low high low shear rate test sample to obtain the evolution of viscosity over time; This method can quantitatively compare the degree of shear thinning and the speed of failure, as well as the degree and speed of recovery.

The significance of structural adhesive thixotropy

The characteristic that the shear stress of the adhesive decreases with time under a certain shear rate. In terms of adhesive technology, the specific performance is as follows: under stirring, the viscosity of the adhesive liquid rapidly decreases, making it easy to apply; When stopped, the viscosity of the adhesive immediately increases and will not flow freely.

The author believes that the term "immediately" in the expression "when stopping, the viscosity of the adhesive immediately increases" refers to restoring the viscosity within a suitable time period, which can ensure leveling performance, uniformity of painting, controllability of adhesive seam thickness, and prevent sagging. If the viscosity decreases and increases in a very short period of time as soon as the application stops, the bubbles in the adhesive will have no time to escape, which will affect the adhesive's bonding strength due to poor defoaming performance.

Slow viscosity recovery can easily cause sagging; If the recovery is too fast, the glue will not flow flat and the defoaming performance will be poor. The author believes that if it happens to be at the equilibrium point of shear recovery performance, it can be considered as a structural adhesive with good thixotropy.

Finally, good thixotropic structural adhesive means for reinforcement engineering:

The structural adhesive has good stability during storage and transportation;

Good construction performance, can reduce labor intensity, and is easy to mix and apply adhesive;

The construction of the facade and elevation is not sagging, and the working surface is cleaner and tidy;

Ensure uniformity of coating and controllability of adhesive seam thickness, with better adhesive effect;

Save glue and engineering costs;

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Two-component modified epoxy resin adhesive, applied to chemical planting reinforcing bar and anchor bolt anchoring

Two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package for anchoring