Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Reinforcement of Steel Structure Factory Buildings

In recent years, there have been multiple steel structure collapse accidents, causing serious social impact and economic losses. The relevant personnel have also been punished or punished accordingly, and in severe cases, even criminal penalties.

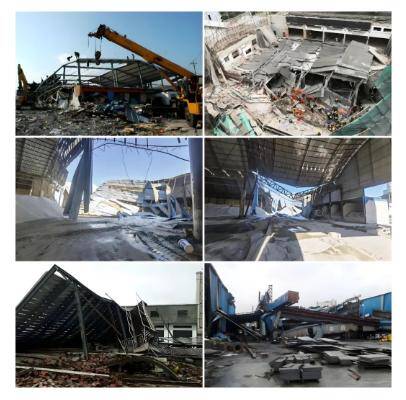

Inventory of collapse accidents in steel structure factory buildings in recent years

The steel shed of a cosmetics packaging company collapsed, resulting in 2 deaths and 10 injuries. The direct cause of the accident was the illegal and irregular construction of the steel structure factory building, without standardized investigation and design. The steel columns and beams were hinged and without inter column support, resulting in poor lateral stiffness. The stability and stable stress of the weak axis direction of the steel columns in the structural system were severely exceeded, and the anchoring length of the anchor bolts at the foot of the steel columns was seriously insufficient;

An accident occurred in the desulfurization tower of the second sintering operation area of a certain steel plant, where the tower bucket fell off and collapsed, resulting in 8 deaths. The direct cause of the accident was that during the ash cleaning operation of the desulfurization device in the second sintering plant, due to the disturbance caused by the peeling of ash on the wall hanging plate and the surge of ash from the lower part towards the discharge port, it caused instability and dumping (the original upper support pipe rusted, fractured and fell off, and the end of the lower support pipe rusted and cracked).

The collapse of a steel structure layered load-bearing platform resulted in 4 deaths and 5 injuries. The direct cause of the accident was that the load-bearing platform was not properly designed and constructed as required, and the supporting columns and beams of the steel structure layered load-bearing platform could not meet the requirements of the working conditions. During operation, the supporting columns and main beams of the steel structure layered load-bearing platform were bent and damaged, leading to the overall collapse of the steel structure layered load-bearing platform.

How to solve the hidden dangers in steel structure factory buildings?

Strengthening steel structure factories that do not meet safety standards is a complex and critical process that requires comprehensive consideration of factors such as the structural characteristics, reinforcement requirements, and construction conditions of the factories. The following are some common reinforcement methods and steps:

1. Structural evaluation and testing

Firstly, it is necessary to conduct a comprehensive structural evaluation and inspection of the steel structure factory building. This includes a detailed inspection of key parts of the factory, such as beams, columns, walls, floors, and roofs, to understand their existing bearing capacity, degree of damage, and stability. By means of non-destructive testing and destructive testing, accurate detection data can be obtained to provide a basis for subsequent reinforcement design.

2. Reinforcement scheme design

Develop targeted reinforcement plans based on structural evaluation and testing results. The reinforcement plan should comprehensively consider factors such as the stress characteristics, reinforcement requirements, and construction conditions of the factory building, and select appropriate reinforcement methods and materials. Common reinforcement methods include increasing the cross-section reinforcement method, post tension frp method, carbon fiber strengthening method, replacing concrete reinforcement method, and bonded external steel reinforcement method. The specific selection should be determined according to the actual situation.

3. Steel structure reinforcement construction

Before construction, it is necessary to make sufficient preparations, including the procurement of construction materials, preparation of construction equipment, and training of construction personnel. During the construction process, the reinforcement plan should be strictly followed to ensure construction quality. At the same time, supervision and management of the construction process should be strengthened to ensure construction safety.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.