Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Select language

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

AFRP, GFRP and CFRP

AFRP

AFRP stands for Aramid Fiber - Reinforced Polymer. Aramid fibers are a class of heat - resistant and strong synthetic fibers. The most well - known aramid fiber is Kevlar. In AFRP, these aramid fibers are used as the reinforcing component within a polymer matrix. The polymer matrix can be epoxy, polyester, or other resins. The aramid fibers provide strength and other mechanical properties to the composite material, and the polymer matrix holds the fibers together and transfers loads between the fibers.

GFRP

GFRP means Glass Fiber - Reinforced Polymer. It consists of glass fibers as the reinforcement material. These glass fibers are typically made of silica - based materials and are very fine. The polymer matrix, usually epoxy or polyester resin, surrounds and binds the glass fibers. Glass fibers are relatively inexpensive and provide good strength - to - weight ratio, making GFRP a widely used composite material in various applications such as construction, automotive, and marine industries.

CFRP is the abbreviation of Carbon Fiber - Reinforced Polymer. Carbon fibers are the reinforcing element in CFRP. These fibers are made from carbon atoms and have a high strength - to - weight ratio and excellent mechanical properties. The polymer matrix, often epoxy resin, bonds the carbon fibers together. CFRP is known for its high strength, stiffness, and low weight and is used in high - performance applications including aerospace, sports equipment, and advanced structural strengthening in civil engineering.

These fiber - reinforced polymers (FRPs) are increasingly used in the field of structural strengthening due to their excellent mechanical properties, durability, and ease of installation.

AFRP for Structural Strengthening

Strength and Stiffness: AFRP provides a good balance of strength and stiffness. Its tensile strength allows it to effectively reinforce concrete and masonry structures. For example, in the strengthening of a reinforced concrete beam, AFRP laminates can be bonded to the tension face of the beam. The aramid fibers resist the tensile forces that occur when the beam is under load, increasing the load - carrying capacity of the beam.

Impact Resistance: AFRP has excellent impact - resistance properties. This makes it suitable for structures that may be subject to dynamic or impact loads such as industrial facilities or transportation infrastructure. In a bridge structure near a railway line, where vibrations and potential impacts from passing trains are a concern, AFRP can provide both strengthening and protection against impact - induced damage.

Fatigue Resistance: It shows good fatigue resistance, which is beneficial for structures subjected to cyclic loading. For instance, in a wind - turbine tower, which is constantly exposed to cyclic wind loads, AFRP can be used to strengthen critical sections and reduce the risk of fatigue - related failures.

GFRP for Structural Strengthening

Cost - Effectiveness: GFRP is a more cost - effective option compared to CFRP. It is widely used in applications where a large area needs to be strengthened, such as in the strengthening of large - scale concrete structures like building facades or retaining walls. The relatively lower cost of glass fibers and the ease of manufacturing GFRP make it an attractive choice for projects with budget constraints.

Corrosion Resistance: GFRP's resistance to corrosion makes it ideal for strengthening structures in corrosive environments. For example, in a coastal building's balconies or in a water treatment plant's concrete tanks, GFRP can be used to prevent the degradation caused by saltwater or chemicals.

Versatility: GFRP can be manufactured in different forms such as sheets, bars, and grids. This versatility allows it to be used in a variety of strengthening techniques. For instance, GFRP bars can be used as internal reinforcement in concrete columns, replacing traditional steel bars, to provide additional strength and resistance to corrosion.

CFRP for Structural Strengthening

High - Strength Applications: CFRP is renowned for its extremely high tensile strength and stiffness. It is the material of choice for high - performance and high - load - carrying - capacity applications. In the strengthening of high - rise building columns, CFRP wraps can significantly increase the axial load - bearing capacity of the columns. In addition, for strengthening prestressed concrete structures, CFRP tendons can be used to enhance the overall performance of the structure.

Minimal Disruption: The lightweight nature of CFRP means that it can be used to strengthen structures with minimal disruption. When strengthening a heritage building, where adding a heavy traditional strengthening material could damage the existing structure or change its aesthetic, CFRP can be a good solution. For example, CFRP sheets can be applied to the interior of a vaulted ceiling to increase its structural integrity without adding significant weight or altering the appearance of the room.

Long - Term Durability: CFRP's resistance to environmental factors such as moisture, chemicals, and UV radiation (with proper coatings) ensures its long - term effectiveness in strengthening applications. In a bridge deck strengthening project, CFRP can provide a durable solution that requires less maintenance over its service life compared to other materials.

Installation Considerations for All FRPs

Surface Preparation: Regardless of the type of FRP used, proper surface preparation of the structure to be strengthened is crucial. The surface should be clean, dry, and free of loose particles, grease, and other contaminants. For example, in the case of concrete surfaces, grinding and sandblasting are often used to create a rough surface that promotes better adhesion of the FRP.

Bonding Agents: High - quality epoxy - based bonding agents are typically used to bond the FRP to the structure. The bonding agent must have good mechanical properties, such as high shear strength and good adhesion to both the FRP and the substrate. The curing process of the bonding agent needs to be carefully controlled to ensure proper bonding.

Quality Control: During the installation process, strict quality control measures are necessary. This includes checking the alignment and orientation of the FRP, ensuring the correct amount of bonding agent is used, and conducting tests such as pull - off tests to verify the bond strength between the FRP and the structure.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

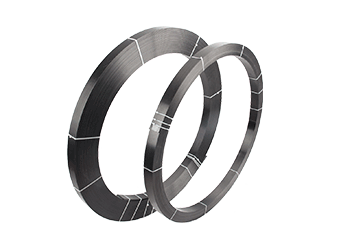

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

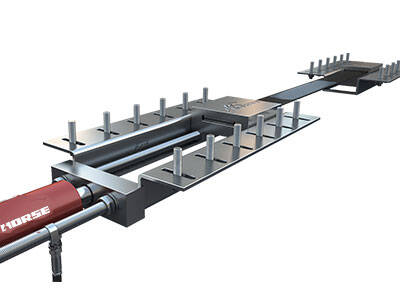

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

Website Map | Corporate | Contact | Privacy