Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

What Is The Purpose Of Silica Sand After Applying Carbon Fiber?

The main purpose of applying silicon sand after pasting carbon fiber is to enhance the adhesion between the carbon fiber cloth and the substrate, and improve the reinforcement effect.

The role and importance of sanding

Increasing surface roughness: Sandblasting treatment can increase the surface roughness of carbon fiber cloth, providing more attachment points for adhesive and making it more firmly bonded in reinforced structures.

Improve adhesion: A rough surface can better interlock with glue, similar to a puzzle, making the adhesion between carbon fiber cloth and substrate tighter, thereby enhancing adhesion.

Improving mechanical adhesion: Sandblasting treatment can enhance the mechanical adhesion of carbon fiber cloth, reduce the impact of external stress on the structure, and improve the durability of the structure.

Removing surface dirt and impurities: Sandblasting can remove dirt, oxides, and other impurities from the surface, ensuring the quality and effectiveness of carbon fiber cloth during the reinforcement process.

Precautions and suggestions

1. Before reinforcing with carbon fiber cloth, the surface of the base layer should be treated to ensure its cleanliness, absence of oil stains and loose materials

2. Before casting sand, the quartz sand or mortar should be screened to remove large particles and impurities, ensuring its quality and uniform particle size.

3. During the process of sanding, it is important to avoid problems such as excessive, insufficient, or missing sand particles as much as possible, while ensuring that the surface of the carbon fiber cloth is evenly covered without any detachment or exposure.

4. After waiting for the glue to be sprayed, the surface quartz sand and carbon fiber cloth can be appropriately compacted to eliminate the conditions of bubbles and detachment.

5. Pay attention to preventing construction waste and other pollutants from reaching the surface of the base layer during the reinforcement process.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

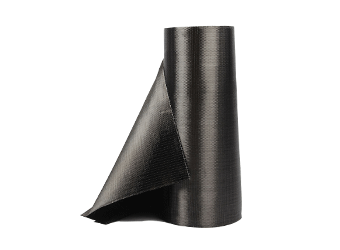

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.