Solutions

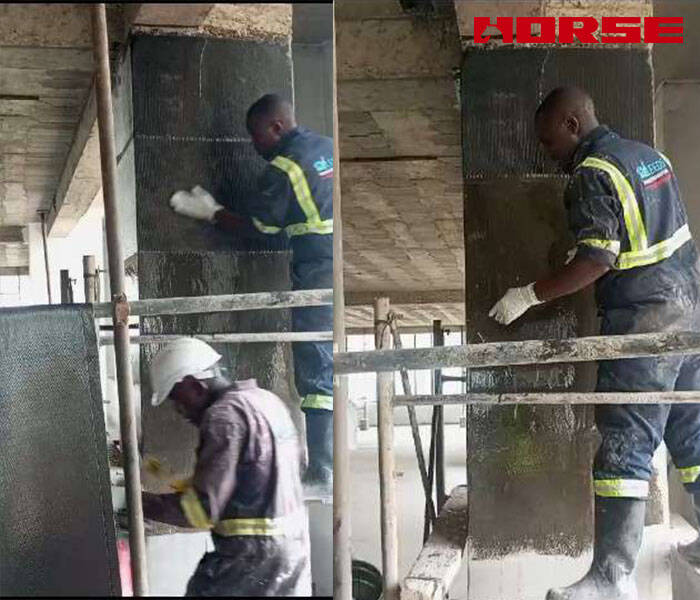

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Applications Of Carbon Fiber In Structural Strengthening

In the fields of architecture and civil engineering, the core value of carbon fiber (primarily used in the form of carbon fiber composite materials such as carbon fiber cloth, carbon fiber plates, and carbon fiber rebar) is to address the pain points of traditional reinforcement/repair methods (such as gluing steel and increasing cross-sections). It is particularly suitable for scenarios where reinforcement is required but space is limited, environments are challenging, or lightweighting is required. Its applicability can be categorized by structural type and core requirements, allowing for precise judgment based on the specific characteristics of the scenario. The following details:

The application of carbon fiber in architecture and civil engineering is essentially to "match material performance with structural problems", mainly covering three categories: concrete structure reinforcement, masonry structure reinforcement, and special structure repair. The specific scenarios are as follows:

Concrete Structural Reinforcement: The Most Popular Application (Over 80%)

When concrete structures (beams, columns, floor slabs, bridges, etc.) experience insufficient load-bearing capacity or cracking due to increased loads, aging damage, or design flaws, carbon fiber is the preferred solution. It is particularly suitable for the following situations:

(1) Strengthening the bearing capacity of frame beams and columns

Applicable problems: Beams with mid-span cracks and support diagonal cracks due to "insufficient bending/shear resistance"; columns with vertical cracks and corner crushing due to "insufficient compression/shear resistance" (e.g., building function transformation: office building converted into archives, load increased from 2.0kN/㎡ to 5.0kN/㎡).

Advantages of carbon fiber:

Pasting carbon fiber cloth (unidirectional cloth, along the load direction) on the bottom of the beam can enhance the bending performance, without the need to remove the original concrete and increase the beam height as in "increasing the cross section" (avoiding the impact on the indoor clear height);

Pasting carbon fiber ring belts (annular winding) on the column side can enhance shear resistance and ductility. Compared with "bonded steel reinforcement", welding is not required (avoiding high temperature damage to concrete) and the column cross-section size is not increased (suitable for narrow areas such as corridors and elevator shafts).

Typical scenarios: reinforcement of frame beams of old office buildings, load upgrade and reinforcement of shopping mall columns, and shear reinforcement of frame columns of underground garages.

(2) Repair of rigidity and crack resistance of floor slabs and basement structures

Applicable problems: Floor slabs with excessive deflection and penetrating cracks due to large spans (such as large-span living rooms and beamless floors in underground garages); basement floor slabs/side walls with water seepage cracks due to "water pressure + shrinkage", and traditional grouting cannot cure them (structural reinforcement is required at the same time).

Advantages of carbon fiber:

Pasting carbon fiber cloth (bidirectional cloth, covering the crack area) on the bottom surface of the floor slab can improve rigidity and inhibit crack expansion. During construction, it is not necessary to occupy the space above the floor slab (without affecting the use of residents);

Pasting carbon fiber cloth on the outside of the basement side wall (with caulking glue) can not only repair cracks and stop seepage, but also enhance the wall's ability to resist lateral displacement (lighter and thinner than "external concrete packaging" and does not occupy underground space).

Typical scenarios: Repair of deflection of large-span floor slabs in residential buildings, reinforcement of water seepage cracks in basement side walls, and crack resistance reinforcement of underground pipe corridor concrete structures.

(3) Lightweight reinforcement of bridges and municipal structures

Applicable issues: Fatigue cracks and insufficient bearing capacity occur in bridge main beams (such as simply supported beams and continuous beams) due to "vehicle load upgrade" (such as from 20 tons to 55 tons); circumferential cracks occur in tunnel linings due to surrounding rock pressure, and traditional reinforcement (such as arch sleeves) will increase the deadweight of the structure (which may exceed the upper limit of the foundation bearing capacity).

Advantages of carbon fiber:

Carbon fiber plates (high strength, high modulus, easier to construct than carbon fiber cloth) are pasted on the bottom/side of the bridge main beam to improve the bending bearing capacity without increasing the deadweight (for example, after the reinforcement of a national highway bridge, the traffic load increased by 40%, and the deadweight only increased by 0.5%);

Carbon fiber cloth (cut into rings) is pasted on the inside of the tunnel lining to resist the radial pressure of the surrounding rock and has a fast construction speed (single ring lining reinforcement only takes 2~3 hours and does not affect tunnel traffic).

Typical scenarios: fatigue reinforcement of highway bridge main beams, shear reinforcement of urban viaduct piers, and repair of cracks in subway tunnel linings.

(4) Repair and reinforcement of prestressed concrete structures

Applicable issues: Prefabricated box girders and prestressed floor slabs experience deflection and web cracks due to "prestress loss" (such as corrosion of steel strands and failure of anchors); cracks appear in the joints of prefabricated components of prefabricated buildings (such as joints of composite slabs), affecting the integrity.

Advantages of carbon fiber:

Pasting "carbon fiber cloth + prestressed tensioning" (i.e. "external prestressed carbon fiber reinforcement") on the bottom surface of prestressed box girders can replenish prestress loss and restore structural rigidity (avoid further deflection of box girders);

Pasting carbon fiber cloth on both sides of the joints of prefabricated components (arranged across the joints) can enhance the tensile strength of the joints and prevent crack expansion (more durable than "grouting repair").

Typical scenarios: Prestressed repair of prefabricated box girders on highways and reinforcement of joints of composite slabs in prefabricated residential buildings.

Seismic and crack-resistant and older buildings

Masonry structures (brick walls and columns) and older buildings (such as brick-timber and brick-concrete structures) are important applications for carbon fiber due to their brittleness and poor seismic performance. They are particularly suitable for:

(1) Masonry load-bearing walls with insufficient seismic resistance

Applicable issues: The seismic resistance of old brick-concrete residential buildings (e.g., those built before 2000) is only 6 degrees, which needs to be increased to 7-8 degrees. Traditional methods (e.g., adding structural columns) will damage the walls and occupy indoor space.

Advantages of carbon fiber: Pasting "carbon fiber cloth grid" (bidirectional cloth, spacing 200-300mm) on the surface of the load-bearing wall can enhance the shear resistance and ductility of the wall (reducing the risk of wall cracking and collapse during earthquakes) without damaging the wall decoration layer (only 2-3mm thickness is increased after construction).

Typical scenarios: Seismic reinforcement of brick-concrete residential buildings in old communities, and reinforcement of load-bearing walls of historical buildings (e.g., brick-wood structures from the Republic of China).

(2) Repair of the bearing capacity of masonry columns and chimneys

Applicable problems: Brick columns (such as load-bearing brick columns in factory buildings and fence columns) crack and become loose due to "long-term pressure"; brick chimneys develop cracks in the tube wall due to "temperature changes + flue gas corrosion", affecting the stability of the structure.

Advantages of carbon fiber: Wrapping carbon fiber rings around brick columns (annular bonding) can enhance the compressive and shear resistance (avoiding column collapse); pasting carbon fiber cloth (vertical + annular) on the outside of the chimney tube wall can repair cracks and resist lateral pressure on the tube wall (more durable than "applying cement mortar", and lighter in weight without increasing the foundation load).

Typical scenarios: Reinforcement of brick columns in old factories and repair of cracks in industrial brick chimneys.

What Are The Applications Of Carbon Fiber In Civil Engineering?(2)

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer(CFRP) plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) strip for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Prestressed carbon fiber reinforced polymer(CFRP) laminate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.