Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

80% of the structural cracks are caused by deformation, and about 20% of the cracks are caused by load, and sometimes two kinds of cracks are fused together.Recommended crack repair products: HM-120ML crack repair adhesive, HM carbon fiber fabric, HM pre-stressed CFRP laminate system

Any damage and failure of concrete structure is first manifested as cracks in concrete. Therefore, the analysis of concrete diseases should be based on the analysis of cracks in concrete structures.

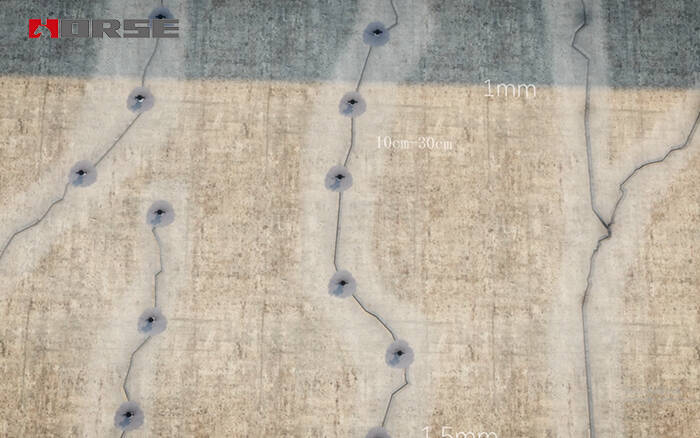

The cracks in the concrete structure are caused by the initial defects in the material and the expansion of the micro cracks. The cracks in concrete can be divided into two categories.

1. Cracks caused by external loads are called structural cracks, also called load cracks.

2. The cracks caused by deformation are called non structural cracks, also called non load cracks. Such as cracks caused by shrinkage of concrete, such as temperature change

Among the two kinds of cracks, 80% of the structural cracks are caused by deformation, and about 20% of the cracks are caused by load, and sometimes two kinds of cracks are fused together.

1.Through reinforcement, the integrity of the structure and component is maintained.

2. Resist the invading medium to induce corrosion of steel bar and prolong the service life of the structure.

2. Restore the function of the structure to improve its waterproof and impervious ability.

3. Improve the appearance of the structure, eliminate the psychological pressure caused by cracks on people.

4. Improve the appearance of the structure

1 surface repair method (or FRP strengthening method)

Recommended products: HM-120ML crack repair adhesive, HM carbon fiber fabric, HM pre-stressed CFRP laminate system

2 low pressure slow injection repair (injection)

The repair glue is injected into the fracture cavity with a certain pressure. This method is suitable for dealing with 0.2<, <1.5mm static fracture, perforation cracks and honeycomb partial defects.

Recommended products:HM-120L crack injection adhesive

3 pressure grouting method

Within a certain period of time, the grouting material is pressed into the fracture cavity with higher pressure (determined by grouting product instructions). This method is suitable for dealing with large structural penetrative cracks, large cellular concrete honeycomb defects and deep and winding cracks.

4 filling seal method

On the component surface along the crack to straddle cut U or V shaped groove, and then filled with modified epoxy resin or elastic caulking material necessary to fiber composite closed surface; this method is suitable for processing >0.5mm activities and static crack crack.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength crack sealing repairing adhesive for the fracture surface of concrete crack

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack