Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Most structure is reinforced with carbon fiber reinfroced polymer fabric(high strength ,high modulus). Why don't we choose basalt fiber for structural strengthening?

1. Low tensile strength

We know that the tensile strength of carbon fiber can reach 3800MPa, equivalent to 10 times of steel, and the mechanical properties are stable. It is a new advanced material for structural reinforcement.

However, the strength of basalt fiber can not reach the requirement of building reinforcement, and it can be broken by hand.

2. Low elastic modulus

Elastic modulus is a "touchstone" for testing the properties of fiber materials, such as carbon fibers, with high elastic modulus, small deformation and excellent performance.

The modulus of elasticity of basalt fiber is very low, and the production process has not been finalized. It can not be used for structural reinforcement.

3. Alkali resistance is inferior to carbon fiber

Basalt fiber is a silicate fiber, and its alkali resistance is not as good as carbon fiber.

4. Durability is not strong

The weathering resistance of basalt fiber is poor. After 10 years, the material itself is basically the same as the soil slag. Reinforced with carbon fiber, life is more than 50 years.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

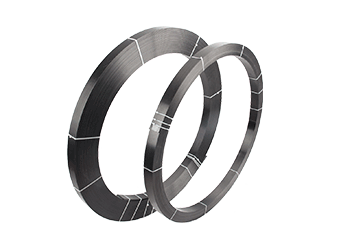

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.