Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

So, as the leading brand of domestic strutural reinforcement materials, how can HM carbon fiber fabric solve these problems at the source through quality control?

In the construction of carbon fiber reinforced plastics (CFRP) reinforcement, the quality of carbon cloth is very important. Because of the aging of equipment and rough technology, there are many poor quality carbon cloth on the market. Common problems are: wool, joints; wavy, big belly; strength is not up to standard; stick hollow; stiff, easy to fall off; glue is not suitable, difficult to soak.

So, as the leading brand of domestic strutural reinforcement materials, how can HM carbon fiber fabric solve these problems at the source through quality control?

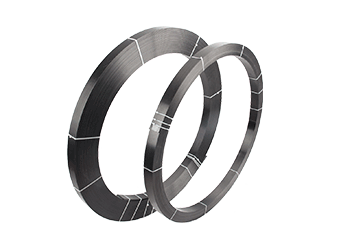

1. Preferred imported aviation grade raw yarn

Imported yarn : uniform use of imported carbon yarn, relative to domestic yarn roughness, unstable performance, imported carbon yarn quality, defect-free, can ensure the same batch of quality stability.

High strength: monofilament strength 5400Mpa, monofilament high strength, molding carbon fiber fabric strength is high.

The length of monofilament is 5000 meters: The code for acceptance and acceptance of construction quality of building structure reinforcement works GB50550-2010 4.5.5 stipulates that the warp breakage of carbon fiber fabrics (including single and double roots) should not exceed 2 places per 100m.

The advantage of imported carbon monofilament length of 5000 meters is that in the process of weaving, no weft breakage, fewer joints, reduce strength loss, to ensure the high strength of carbon cloth.

Wool-free, hairing: Carbon fiber as a load-bearing structure reinforcement materials, the appearance of serious defects in quality, usually affect the structure, members of the mechanical performance or durability.

Effects of monofilament quality on workers: monofilament quality is not good, the formation of carbon cloth hair, hair phenomenon is very serious, especially in hot summer, the air floating carbon fiber dust is easy to cause skin allergy. Hummer uses high quality imported carbon wire, forming carbon cloth without wool, joints, reduce the risk of allergy workers, reduce the worker's construction burden.

2. German intelligentized machine

Active weft insertion: abandon the drawbacks of traditional looms, adopt active weft insertion method, carbon filament point-to-point handover, so that each bunch of filament tension tends to be consistent, to minimize the strength loss of carbon fiber.

The computerized precise control system of the warp and weft tension is developed independently. If in the process of weaving, the loom tension is not uniform, the force on each wire is not uniform, then a phenomenon will occur. Where the tension is high, the carbon filament is tight, where the tension is low, the carbon filament is loose, forming bulging, wavy, big belly. Then during the construction process, the glue is applied unevenly, and the bulging area will be lack of glue, forming a hollow drum.

The consequences of the empty drum: the tension of the carbon cloth force, empty carbon cloth is not force, resulting in the tension of the carbon cloth was first pulled, carbon cloth lost effect.

Horse carbon cloth throughout the process of warp and weft tension, computer precision control system, self-developed yarn frame to ensure that each bunch of carbon wire tension constant, small dispersion, to ensure the strength of carbon cloth, from the root to eliminate the phenomenon of empty construction of carbon cloth.

Weaving uniformity and smoothness: Carbon fiber cloth surface smoothness determines whether the carbon cloth is easy to penetrate and stick, and carbon cloth stick firmly to play its performance. Horse intelligent knitting equipment makes the carbon filament uniform distribution, straight arrangement, compact yarn, good flatness, easy construction, eliminate empty drum.

Soft and moderate: Carbon cloth reinforcement often need to wrap U-shaped hoop, if the carbon cloth is too hard, it is not easy to construct, it is also easy to cause cloth dropping phenomenon.

Carbon cloth is moderate in hardness, good in bonding, convenient in construction, easy to operate, refuse to be rigid, not easy to fall off, and prevent rework.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair