Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Prestressed CFRP plate is one of the most common external prestressing reinforcement methods in the design and construction of civil engineering in China. It is a method of applying a pre-tension stress to CFRP and anchoring it to the member to be strengthened.

Prestressed carbon fiber plate reinforcement technology for bridge

Prestressed CFRP plate is one of the most common external prestressing reinforcement methods in the design and construction of civil engineering in China. It is a method of applying a pre-tension stress to CFRP and anchoring it to the member to be strengthened.

Prestressed carbon fiber sheet has flexible and variable tension stress range, medium erosion resistance and high long-term stress retention. As a new generation of external prestressing member, it can compensate for the stress loss of steel strand and improve the overall stability of the structure in a certain range.

Defects of Prestressed flat anchorage system

As a new generation of reinforcement technology, prestressing carbon fiber sheet (PCF) has some advantages that traditional reinforcement technology can not match, but it still inevitably has some technical defects, such as:

In the existing pre-stressed flat anchorage system, a major branch of the anchorage form is the wedge-shaped channel of the flat splint. In order to ensure the accuracy of this type of anchorage, the WEDM process is generally adopted (the error requirement is (+0.2mm). However, in the actual processing process, there may still be problems such as too large surface roughness or size not up to the standard, and it is difficult to detect by naked eye or general measuring instruments. These processing problems may lead to carbon fiber board pop-up under high stress conditions, and there are potential dangers to personal safety.

At the same time, in order to make the CFRP board close to the concrete surface, the whole anchorage often needs to slot the concrete in the process of installation. This work is time-consuming, and if the original concrete protective layer is too small, it may lead to the hidden danger of collision with steel bars and can not be installed.

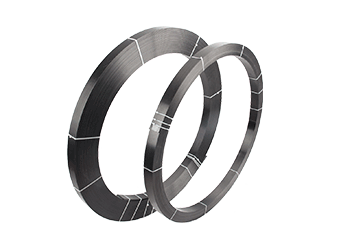

Based on the original anchorage system, Shanghai Horse Construction has developed a new generation of circular anchorage system for prestressing carbon fiber sheet clamping operation through field investigation and technical adjustment and improvement.

The unique application advantages of the new generation circular anchorage system

The new generation of circular anchorage system has the following application advantages:

1. Because the circular channel is an integral whole, there is no machining error and surface roughness problem at the corner of the square splint, which avoids the hidden danger of carbon fiber board popping up. At the same time, the uniformity of circular anchorage also avoids the problem of upside-down installation.

2. The cross-sectional area of circular anchorage decreases gradually from the center to the side, so slotting can be cut according to trapezoidal cross-section. The volume of concrete needed to be removed is reduced by about 40% compared with ordinary square anchorage. The deeper the slotting area is, the smaller the slotting time is, and the probability of collision with steel bars is greatly reduced.

3. The actual WEDM area of circular anchorage is about 15% less than that of ordinary square anchorage, and the weight is reduced by about 30%. It can further control the manufacturing cost and reduce the installation burden of workers.

4. The stress of the circular anchorage is concentrated in the middle, which avoids the arch in the middle of the splint under the condition of large stress, which leads to the unstable clamping and the fracture of the carbon fiber plate.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength carbon fiber reinforced polymer plate adhesive for applying CFRP laminate/strip/plate on the structural members