Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fiber fabric for structural strengthening can greatly improve the service life of buildings and reduce the cost of reinforcement. However, there will be common faults in construction, Horse Construction will share some solution to solve these problem.

The carbon fiber fabric warped around

After the completion of the construction, the carbon fabric often has the edge of the situation, this situation will lead to carbon fiber and concrete contact area smaller. The main reasons for this situation are the following three aspects:

the coating of the film is not in place;

when scraping and pressing with scrapers, it is easy to blow and scrape.

the side of the base surface treatment is not in place.

Preventive measures: before sticking the carbon cloth, we should first position the line, when processing the base surface, we should pay attention to the location of the base surface a little greater than the carbon paste area, about 2cm, including the glue coating, and in the process of scraping and scraping, it should be carefully curettage, no leakage and scraping.

Solution: If a small part of the warping can not be treated, large areas of warping should be re-glued to the warping position for pasting.

Drums produced after the construction of carbon fiber fabric

Anyone who has made carbon cloth paste knows that the most troublesome thing about carbon cloth construction is to pack. There are many reasons for starting bags, but they are mainly in the following aspects:

The adhesive coating is not in place and some parts are not adhered to. After the gel is solidified, it will appear empty.

The problem of the material itself, some of the poor quality epoxy resin will produce some bubbles during the curing process, which leads to the emergence of the drum, and perhaps the carbon cloth itself is not straight, and the drum is produced in the process of stickup.

Preventive measures: quality inspection of carbon cloth. During the construction process, the adhesive should be evenly distributed without leakage.

Solution: if the area of a single empty drum is not more than 10000mm, the injection filling is used to repair it. If the area of a single empty drum is greater than or equal to 10000mm, the empty drum should be cut and reattached to the carbon fiber composite. Some small parts can not be processed, but the total effective contact area between carbon cloth and reinforced components must be greater than or equal to 95%.

The colloid is too thick during the winter construction, and it is not easy to construct.

During winter construction, colloid is often too thick and construction experience is poor.

Solution: the epoxy resin itself is particularly sensitive to the temperature, and the colloid itself will be a normal phenomenon in winter, which is heated by water bath in the construction process, and the alcohol and other organic solvents are strictly prohibited in the colloid.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

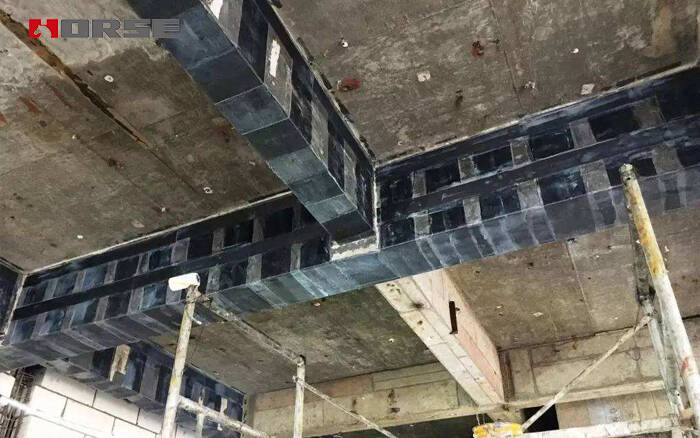

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair