Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Compared with the traditional carbon fiber reinforcement method, the high strength performance of the prestressed CFRP can be effectively used. The reinforcement effect is greatly improved than the CFRP, and it also has the advantages of CFRP reinforcement. It has shown remarkable effects in improving the flexural rigidity, bearing capacity, reducing the structural deformation and restraining the development of cracks.

It can effectively improve the utilization ratio of carbon fiber cloth after adding prestress to carbon fiber, and the prestress can restrain the premature appearance of concrete cracks, which is beneficial to the improvement of the bearing capacity of the components. Due to the prestress restraining cracks, the stress concentration of cracks can be avoided and the CFRP will be stripped off the cracks.

The prestressed CFRP advantages:

1) the components that are reinforced with prestress carbon fiber cloth have greater strain since the carbon fiber cloth has been stressed before being strengthened to the component, and the CFRP can play an early role and play a larger role. Therefore, the reinforced members can obviously improve the cracking load, yield load and ultimate load of the beam, and reduce the deformation of the beam in the use stage and the stress of the main tendons in the beam, and the reinforcement effect of the prestressed concrete bridge is more obvious.

2) prestressed carbon fiber reinforced concrete (CFRP) reinforced concrete members will produce large shear stress at the interface between carbon fiber and structural bond. A reasonable and reliable anchorage method can avoid or delay the breakage of bond stripping between the carbon fiber cloth and the concrete base or the shear stress of the concrete, so that the structure is destroyed before the ultimate tensile strain is not reached, and the material is fully utilized and the brittle failure is avoided.

3) prestressed CFRP reinforced concrete members can improve the use performance of cracks and deformation of components, effectively restrain the development of cracks, reduce the width of existing cracks, and improve the durability of the structure.

4) in cold environment, the bonding of Prestressed CFRP reinforced concrete beams is not affected by low temperature, and the reinforcement effect is not reduced. It shows that the reinforcement method of Prestressed CFRP is suitable for extremely bad environment.

Compared with the traditional carbon fiber reinforcement method, the high strength performance of the prestressed CFRP can be effectively used. The reinforcement effect is greatly improved than the CFRP, and it also has the advantages of CFRP reinforcement. It has shown remarkable effects in improving the flexural rigidity, bearing capacity, reducing the structural deformation and restraining the development of cracks.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

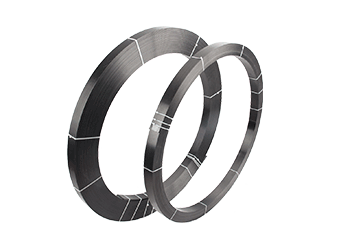

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.