Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

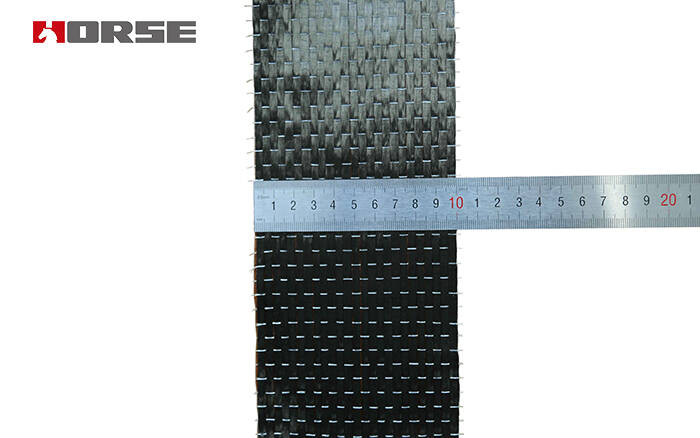

Concrete beam strengthening method: externally bonded carbon fiber and epoxy bonded steel plate,both are bonded to the surface of the concrete member with an adhesive to reinforced by flexural members, reinforced by tension members

Concrete beam strengthening method:

externally bonded carbon fiber

epoxy bonded steel plate

Generally applicable to reinforced by flexural members, reinforced by tension members. Because both are bonded to the surface of the concrete member with an adhesive, and the bonding strength of mainly depends on the concrete, so the strength level of the reinforced concrete should not be lower than C15, section of the tensile stress strength shall not be less than 1.5MPa. At the same time. It should not be higher than the ambient temperature of 60 ℃, relative humidity should not exceed 70%, the surrounding environment without corrosive chemicals. In the structural reinforcement, it is possible to improve the safety, suitability and durability of concrete structures through a combination of techniques such as steel jacketing, planting rebars, repair of concrete cracks, and sealing of concrete surfaces.

The bonding steel plate method for compressing and strengthening components with larger power, additional anchoring measures should be added; for example, two planting bolts or through beams shall be provided for every 100mm, and the anchoring plates shall be used for pulling bolts. Steel plate can be welded anchor, but also anchorage, so the anchor method is more flexible than carbon fiber.

Carbon fiber is generally only through the adhesive , the carbon fiber layer is generally limited to 5 layers.

Therefore, in the case of need to greatly increase the bearing capacity , bonding steel plate is better than the carbon fiber strengthening method.

Stick steel plate can be applied to the pressure parts of the beam, but carbon fiber can not. For example, the frame structure of the edge beam, the edge plate to bear the negative moment, the pressure zone can be bonded steel reinforcement. When the reinforcement ratio of the tension zone is relatively high, if the reinforcement zone is further increased in the tension zone, it may become a super-reinforcement beam. When the concrete in the compression zone is damaged or other defects are not convenient to reinforce the tension zone, the carbon fiber method Can not replace the sticky steel method.

Carbon fiber compared with steel plat is belong to the inert material, not rust, nor susceptible to corrosion of harmful media, without maitance, can be used in environments with relative humidity above 70%.

After bonding steel plate need to carry out the necessary surface protection, such as adding epoxy mortar or cement mortar protective layer, the degree of corrosion of steel is more difficult to estimate, reducing the reliability of components, an increase of maintaince costs after reinforcement.

In the sametime, in order to facilitate the pressurization of the steel plate during the construction process and prevent the steel strip from peeling off, bolt anchoring must be taken for the steel-sticking method, which inevitably causes some damage to the original structure. Therefore, the steel plate bonding method is generally not suitable for reinforcing with larger reinforcement density of reinforced structure.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good thixotropy carbon fiber leveling adhesive for concrete surface repairing

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement