Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

unidirectional carbon fiber cloth

Unidirectional Carbon fiber Cloth is a strong, lightweight composite that can be used with polyester or epoxy for structural strengthening and concrete repair.

Frequently asked questions: unidirectional carbon fiber cloth

1 what is unidirectional carbon fiber cloth?

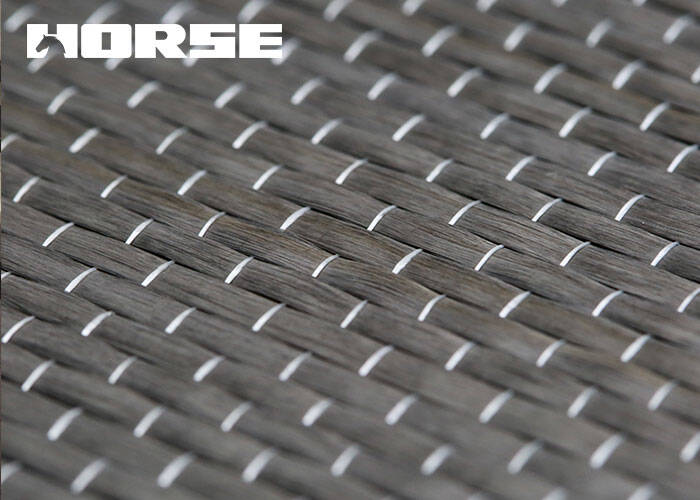

The unidirectional carbon fiber cloth is in one direction (usually meridian) with a large amount of carbon fiber, with only a small amount of carbon fiber in the other direction and usually thin carbon fibers in the other direction, so that all the strength of the cloth is in the same direction.

2 What is the connection between carbon fiber prepreg and unidirectional carbon fiber cloth?

Carbon fiber prepreg is actually a pretreatment product of unidirectional carbon fiber cloth. Mainly used in the industrial field, the requirements for transportation and storage are relatively high, requiring refrigeration.

3 Why are there different weaves of carbon fiber cloth?

Carbon fiber comes in different weaves optimized for different uses. For example, unidirectional cloth is good for adding strength and stiffness in one direction, the standard twill weave is a good all-purpose cloth. Plain weave is good for delicate layups and some patterns are just designed for a unique look!

Choosing the right one-way carbon fiber cloth

Horse has a selection of genuine non-woven unidirectional cloths. In our unidirectional cloths, the fibers are bound by a small amount of polyester binder, and the content of polyester binder is less than 3% of the overall structure. They are finished with mildly sizing chemicals to prevent the fibers from wearing out during processing. The adhesive is only used on one side of the material to provide a clean carbon facing surface without twisting or crimping the fibers. Other brands of unidirectional cloths are sometimes slightly woven in the binder, which is not a true unidirectional cloth. Even slight weaving will reduce the maximum unidirectional strength.

All of Horse's unidirectional cloths are 100 meters long. Easy to use, easier to store, carry and transport. All of our cloths have relatively high tensile modulus to achieve excellent stiffness.

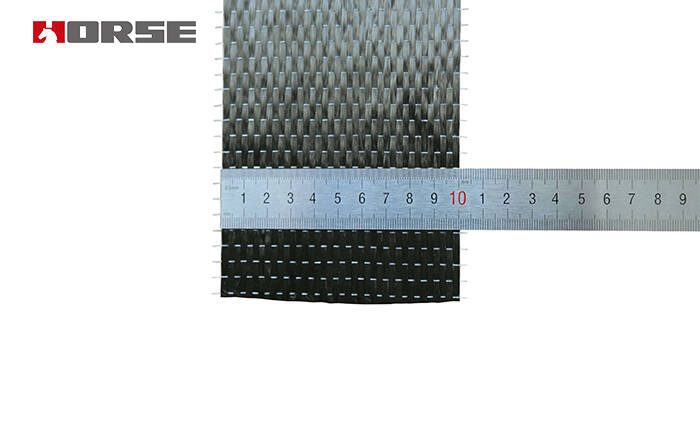

Horse currently offers three conventional unidirectional carbon fiber cloths. The following is a summary of each cloth, so you can find a cloth that can meet your unique needs. We also have other specifications, please consult customer service staff for details, 230gsm, 430gsm, 450gsm, 530gsm, 900gsm.

Horse 12K unidirectional carbon fibre cloth for structural strengthening technical datasheet

| Style | Grade | Reinforcement Yarn | Weave | Tensile Intensity (MPa) | Tensile Modulus (GPa) | Elongation (%) | Thickness (mm) | Width |

|---|---|---|---|---|---|---|---|---|

| HM-20 | A | 12K | Unidirectional | ≥3500 | ≥230 | 1.8 | 0.111 | 10, 15, 20, 25, 30, 50, 60cm |

| HM-30 | A | 12K | Unidirectional | ≥3500 | ≥230 | 1.8 | 0.167 | 10, 15, 20, 25, 30, 50, 60cm |

| HM-60 | A | 24K | Unidirectional | ≥3500 | ≥210 | 1.8 | 0.333 | 10, 15, 20, 25, 30, 50, 60cm |

Advantages of Horse unidirectional carbon fiber cloth

Unidirectional carbon fiber Unidirectional carbon fiber is a kind of carbon fiber reinforced material, it is a non-woven cloth, all the fibers of which extend in a parallel direction. With this style of cloth, there are no gaps between the fibers, and the fibers lie flat. No cross-sectional weave divides the fiber strength in half in the other direction. This allows a concentrated fiber density that provides maximum longitudinal stretch potential-greater than any other cloth. For comparison, this is 3 times the longitudinal tensile strength of structural steel at one-fifth of the weight density.

Likewise, composite parts made of carbon fibers can provide ultimate strength in the direction of the fiber particles. Therefore, composite parts that use unidirectional carbon fiber cloth as their exclusive reinforcement provide maximum strength in only two directions (along the fiber direction) and are very stiff. This directional strength characteristic makes it similar to wood, which is an isotropic material. During part placement, unidirectional cloths can be overlapped in different angular directions to achieve strength in multiple directions without sacrificing rigidity. Similarly, in the web-laying process, unidirectional cloths can be woven with other carbon fiber cloths to obtain different directional strength characteristics or aesthetics.

The weight of the unidirectional cloth is also very light. It is lighter than similar woven products. In this way, the structure of precision parts can be more strictly controlled, and precise engineering design can be carried out in the stack.

Moreover, compared with woven carbon fiber, unidirectional carbon fiber is also more economical. This is due to its lower total fiber content and less weaving process. This can save the production cost of parts that seem to be expensive but high-performance.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.