Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

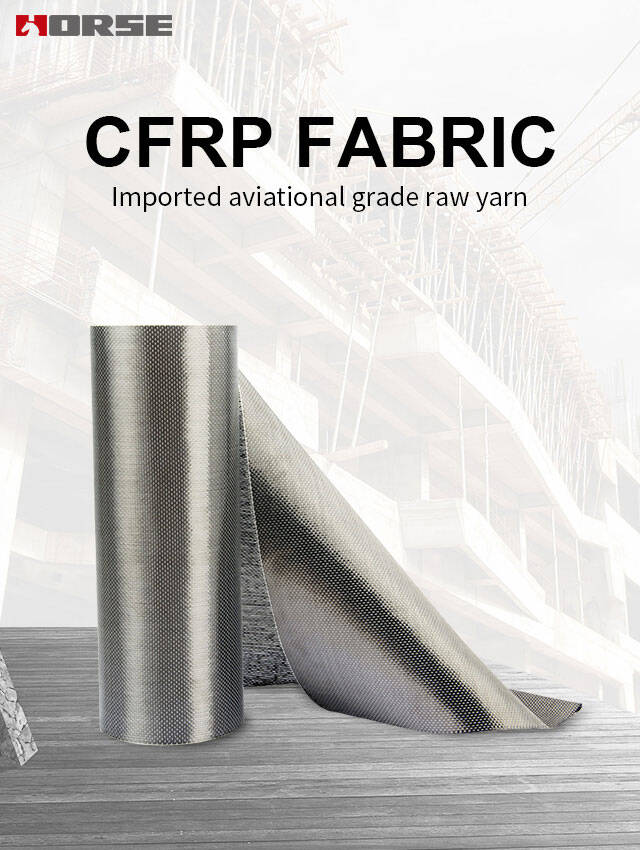

unidirectional carbon fiber fabric for structural strengthening

Highlights - Unidirectional Carbon Fiber Fabric

•Unidirectional carbon fiber fabric has a unique tensile strength greater than steel, but its weight is only one-fourth.

• Unidirectional carbon fiber fabric is recognized as the mainstream construction material for the repair, strengthening and retrofitting of concrete structures.

•Compared with steel bars, unidirectional carbon fiber fabrics have high resistance to chloride ions and chemical attack.

Structural Strengthening - Unidirectional Carbon Fiber Fabric+Adhesive System

Carbon fiber base (CFRP)

The most common FRP system used for concrete reinforcement is carbon fiber based (CFRP). Unlike glass fiber-based systems, carbon has excellent mechanical properties and higher tensile strength, stiffness and durability. The use of prefabricated CFRP bars and slabs is generally limited to straight or slightly curved surfaces; for example, the top or bottom side of slabs and beams. Prefabricated FRP elements are usually rigid and cannot be bent on site to wrap around a column or beam.

However, FRP fabrics can be made of continuous unidirectional paper provided in rolls, can be easily customized to fit any geometric shape, and can be wound on almost any contour. FRP fabric can be glued to the tensile side of the structural member (ie, flat plate or beam) to provide additional tensile strength and increase bending strength. Around the web of the joist and beam to improve its shear strength. And wound on the column to increase its shear strength and axial strength, and improve ductility and energy dissipation behavior.

Adhesive system

The bonding system used to bond the FRP to the concrete substrate may include a primer, which is used to penetrate the concrete substrate and improve the adhesion of the system. Epoxy putty can fill small surface voids in the substrate and provide a smooth surface combined with the FRP system. Epoxy resin used to soak fabric and bond it to the prepared substrate. And a protective coating to protect the bonded FRP system from potential environmental and mechanical influences. Generally, ultraviolet light (UV) has a negative effect on FRP-reinforced epoxy resins, but acrylic and cement coatings and other types of coatings can be used for protection.

Unidirectional Carbon Fiber Fabric Application - Structural Strengthening

Seismic Retrofit | Load Rating Upgrade | Damage Repair | Defect Remediation | Blast Mitigation |

Shear strengthening | Increased live loads | Deterioration/corrosion | Size/layout errors | Hardening |

Displacement/ductility | New equipment | Blast/vehicle impact | Low concrete strengths | Progressive collaps |

Life safety | Change of use |

| Confinement | Usually, restrictions are applied to the member's compression state to enhance its bearing capacity or increase its ductility in the event of an earthquake escalation. Unidirectional carbon fiber fabric is a reliable restraint device for reinforced concrete components. |

| Shear Strengthening | The flexibility of unidirectional carbon fiber fabric allows it to be applied to irregular cross sections, which can appear in RC beams and columns. The combination of shear reinforcement and high modulus carbon fiber fabric and the combination of bending reinforcement of CFRP plate is the best. |

| Seismic Strengthening | This is usually a combination of seismic, shear and dynamic loads. Historically, an important area is the wrapping of bridge pillars to prevent premature damage in earthquakes. |

| Impact Strengthening | The unidirectional carbon fiber fabric can absorb the high energy consumption caused by the impact of cars or large ships to protect the chromatographic column from collapsing. |

| Flexural Strengthenin | Not only can steel plates or Cfrp plates be used, but also non-directional carbon fiber fabrics can be used to enhance the flexibility of structural elements, especially when the performance of the matrix is low. For long fabrics used for flexural reinforcement, special attention must be paid to the correct arrangement of the load-bearing fibers |

| Blast Mitigation | Embassies, airports, government buildings, bridges and other sensitive buildings are usually targets for terrorists to manufacture and destroy weapons of mass destruction. FRP composite material is an effective method for sandblasting and hardening existing structures without changing the purpose of the facility. |

| Masonry Strengthening | FRP composites are an excellent way to upgrade and repair masonry structures. FRP combines the positive properties of high tensile strength and the load-bearing capacity of masonry walls to form a composite effect. They are also very suitable for repairing unreinforced masonry walls, especially in seismic areas where ductility can be improved. |

| Pipe Strengthening | Due to the aging of the world’s infrastructure, it’s not uncommon for pipes to burst and cause floods and catastrophic damage to major cities. Unidirectional carbon fiber fabrics have been used to reline the interior or exterior of concrete and steel pipes that have degraded due to corrosion damage, distress, overload, or seismic events. |

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.