Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

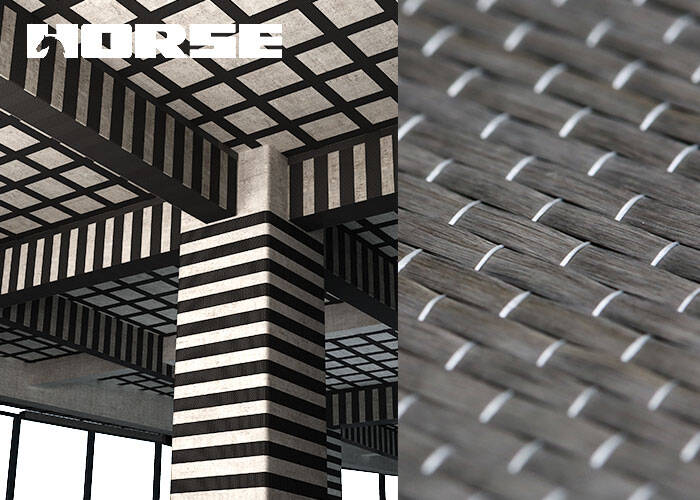

carbon fiber structural strengthening

Horse carbon fiber strengthening system brings over

20+

years experience with installations all over the world

60+

export countries all over the world

70000+

projects all over the world

Your best partner for carbon fiber structural strengthening-Horse Construction

Shanghai Horse Construction Co., Ltd is a professional manufacturer of structural strengthening materials in China. Its main products are Horse carbon fiber materials and all kinds of epoxy resin adhesive. Started from 2006, Horse Construction has been focused on structural strengthening materials for more than 10 years. Has the great mission "producing the highest quality structural strengthening materials, removing safety loopholes of concrete structures to save lives and buildings" . Under that mission, every one in Horse Construction is working extremely hard to provide the best products and services for our clients.

Horse Construction have six structural strengthening systems cover all of the structural strengthening industry. Its main products are carbon fiber materials and all kinds of epoxy resin adhesive, including more than 30 structural strengthening materials. Six structural strengthening system: FRP composite strengthening system, prestressed CFRP laminate system, anchoring and fixing system, steel plate bonding system, concrete crack repair system, bridge bearing system.

Horse construction accept structural strengthening products agency to achieve localization services. So far, set up agents in Asia, North America, South America, Europe and other regions. Our structural strengthening products and services have covered over 60 countries and regions, We are purposing to extend our sales network around the world in 3 years.

First of all, Horse is a manufacturer of structural strengthening materials, which is cost-effective and cost-effective compared with similar products. Secondly, the quality of the products is good. All structural strengthening products have gone through 30 processes, 4 layers of self-inspection and 3 layers of re-inspection. Third, productivity meets the needs of large and urgent projects. 7 carbon fiber production lines, with a daily output of more than 10,000 square meters of carbon fiber.

Service is the promise of the enterprise, the soul of the brand. As the leader of the structural reinforcement materials industry in China, Horse Construction’s lean sevice would accompany with you throughout the whole sales term to offer the full set of solutions with innovative consultations and butler-like service.

Horse structural strengthening materials have been used in more than 70,000 projects and sold to 60 countries. It is suitable for the strengthening and repair of various structural types and structural parts, such as beams, slabs, columns, roof trusses, piers, bridges, cylinders, shells and other structures. And for reinforcement and seismic reinforcement of concrete structures, masonry structures, and wood structures in port projects, water conservancy and hydropower projects.

Why carbon fiber structural strengthening system?

The use of a building or civil engineering structure may change throughout its life, for example, its function may change, load may increase, or higher building standards are required, and the structure must be made to meet the requirements. Without affecting the original design or form, historical or landmark buildings may need to be reinforced in a discrete manner.

In order to prolong the service life of the structure for decades, structural reinforcement is a safe and reliable choice. Horse provides comprehensive and complete structural reinforcement materials for various structural reinforcements. Whether the requirement is to increase bending strength, shear strength or seismic resistance, the tested and proven Horse reinforcement material system can be used in reinforced concrete, steel, wood and masonry load-bearing structures.

Full range of carbon fiber structural strengthening materials to meet local requirements

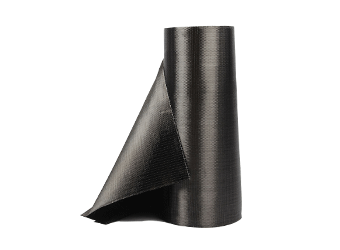

Carbon fiber reinforced polymer (CFRP) fabrics

Carbon fiber reinforced polymer (CFRP) plates

Carbon fiber structural strengthening application

Slab — Adds collector reinforcement, negative and positive moment flexural capacity

Slab opening — Trim reinforcement

Beam — Laminates or fabrics for flexure and/or collector reinforcement, fabrics for shear stirrup reinforcement and potential use of FRP anchors (shown in orange for contrast)

Wall — Stiffening, flexural, shear or tensile reinforcement

New wall opening — Trim reinforcement

Column wrapping — Full column wrap to achieve required strengthening, possibly with additional near-surface mounted laminates or fabric for flexure; effective solution for under-reinforced column ties

Protective coating — High-performance protection against exposure, corrosion, chemical attack, abrasion, fire resistance and other environmental factors

Carbon fiber structural strengthening features

High strength to weight ratio

Excellent resistance to creep and fatigue

Extremely durable

Low aesthetic impact

Advantages of carbon fiber structural strengthening

Adds strength without adding dead load

Withstands sustained and cyclic load conditions

Extremely resistant to wide range of environmental conditions

Easy to conceal

Your best partner for carbon fiber structural strengthening-Horse Construction

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.