Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

According to the quality of carbon fiber fabric, the quality of carbon fiber fabric produced by Horse Construction is basically the same as that of developed countries. Because many users are not very aware of this situation, they choose other developed countries, so our carbon fiber fabric is difficult to compete with other imported products.

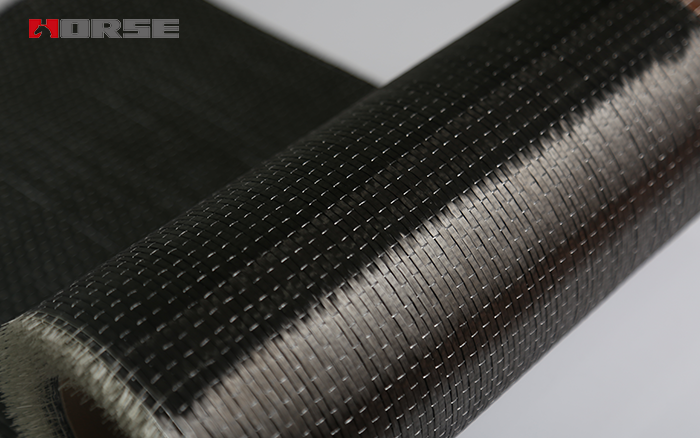

Carbon fiber is a kind of high-tech fiber-like carbon material. It is made by decomposition of organic matrix fibers in inert gas at 1000-3000 C. Carbon fiber is black, with high strength, light weight, conductivity, high temperature resistance, corrosion resistance, small expansion coefficient and other characteristics. The main forms of carbon fiber products are: fiber, carbon cloth, prepreg blank (cloth), chopped fiber, carbon powder, carbon rope and so on. Among them, carbon cloth refers to the fabric made of carbon fiber. Prepreg blank is a uniform arrangement of carbon fibers in radial direction (or woven into a warp-and-weft carbon fiber cloth), and then preimpregnated with resin to convert it into sheets (or preprepreg). Chopped fibers refer to the short cut of carbon fibers. Carbon powder is the carbon fiber powder that is removed from the carbon fiber after grinding. Carbon fiber cloth is mainly divided into: unidirectional carbon fiber fabric (mainly used for building reinforcement), bidirectional carbon fiber fabric (mainly three primary organization), warp-knitted carbon fiber cloth, multi-axial carbon fiber cloth and so on.

1. The weaving process and control points of carbon fiber fabric.

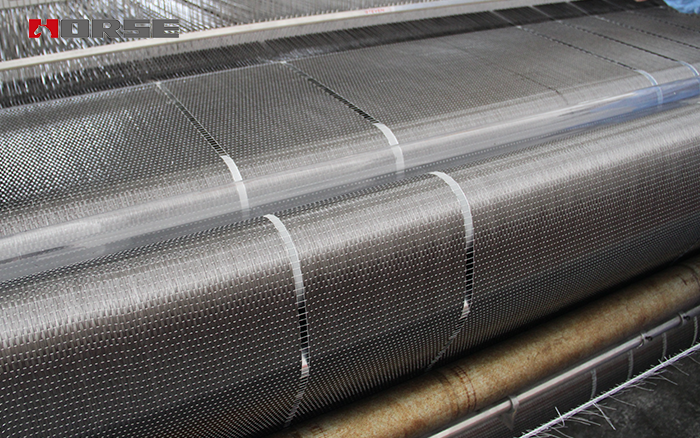

Weaving must be done with appropriate tension, because the warp tensile strength of carbon fiber is very strong, from the warp tensile strength, to meet the weaving is no problem. However, the weft strength of carbon fiber is very low, and it is very difficult to wear, it is easy to hairing in weaving, it is easy to cause carbon fiber hairiness in weaving clogging warp channel, hairiness winding each other, not open the shuttle, and even cause carbon fiber warp yarn broken end, thus affecting weaving. How to weave carbon fiber cloth is a very detailed job. Based on years of production experience, the company has independently developed a high-performance loom suitable for knitting special fibers. Especially for the weaving of carbon fiber cloth, a set of special production technology and control points suitable for different specifications and varieties of carbon fiber cloth have been worked out. With perfect testing methods, carbon fiber cloth with excellent appearance and internal quality has been successfully woven.

1.1 Tension control of warp yarn

Weaving carbon fiber loom loom does not use the weaving shaft, but directly on the warp frame. The warp path should be smooth and friction should be minimized. The warp tension control is made up of V or S type tension rollers and upper and lower pressure tension rollers to ensure the uniformity of warp tension and warp sheet tension needed for weaving, so as to open the shuttle and facilitate weaving. Here the upper and lower pressure roller in use is the best active let-off, but the premise must be synchronized with the loom curl, power can be provided by the loom let-off mechanism of the original power.

The tension control device for a single warp on the warp frame is generally not used. According to experience, the tension between the warp frame and the tension roller is very small, as long as the warp yarn is not very loose. In fact, the tension required by loom weaving is mainly provided by tension pressure roller. If tension is applied to the warp yarn from the tension rack, it will easily cause the carbon fiber filament to wool, which is not conducive to weaving, so we must control the warp tension and the uniformity of warp tension. When the tension is appropriate and uniform, the carbon fiber cloth will look flat in appearance, especially in warp direction. Warp color difference is generally due to the uneven tension of carbon fiber warp yarn, the size of the buckling wave formed on the cloth surface is not the same, very few are caused by the color difference of carbon fiber itself, but the quality of carbon fiber itself is not within the scope of our discussion of weaving.

1.2 Modification of weft insertion

Some users are very demanding on the quality of carbon fiber cloth. For example, when a rocket loom is used to weave a 1k/1k11/11 (root/cm) 800m bi-directional carbon fiber cloth, the user requires that the damage of the carbon fiber be minimized. In order to reduce the wear of warp yarn, rigid rocket weft insertion is adopted. Flexible rapier belt and carbon fiber rod are bonded together to form rigid rapier belt, and the inverted rapier hook within the fabric surface is removed. In this way, the warp yarn will not be rubbed against the barb shear hook at each beating, and the smooth and tidy surface of the fiber cloth can be guaranteed to minimize the damage to the carbon fiber.

Some users require a folded edge of carbon fiber cloth, because the shuttleless loom produces a woolen edge of carbon fiber cloth, in this case can be woven with a shuttle loom. Because of the processing of carbon fiber, the loom can not weave too fast, but it is difficult to weave carbon fiber cloth with shuttle loom under the condition of low speed to ensure the normal weft insertion. Because the traditional shuttle loom, whether it is down shuttle mechanism or in the shuttle mechanism, the successful completion of shuttle not only depends on the size of the shuttle force, but also depends on the speed of the loom to give the inch strength. That is to say, in the case of low speed, how to increase the shuttle force can not guarantee the shuttle to reach the opposite side shuttle box smoothly, to reform the shuttle mechanism, can use the original power device of the loom into spring force shuttle, so as to solve this problem.

In addition, the shuttle weft insertion outlet should also be reformed on shuttle looms, and the shuttle outlet should be changed into smooth outlets of different sizes according to the needs of weaving different K number carbon fibers.

2. Market convergence of carbon fiber fabric in China

2.1 Market obstacles to the application of CFRP products in China

In the construction, bridge and other fields, sometimes it is necessary to use carbon fiber cloth to reinforce. The quality of carbon fiber cloth used for reinforcement is mainly determined by the quality of carbon fiber used. As long as good weaving technology is available, good quality carbon fiber cloth can be produced with good carbon fiber. At present, most of the carbon fiber cloth used in China is woven by domestic manufacturers. The imported carbon fiber cloth is mainly used for building reinforcement of carbon fiber unidirectional cloth. According to the weaving of carbon fiber cloth, the quality of carbon fiber cloth produced by China's better weaving enterprises is basically the same as that produced by foreign developed countries, and there is no essential difference. Because many domestic users are not very aware of this situation, in order to avoid risk and responsibility, we do not use China's carbon fiber cloth. In fact, China can also produce the same quality carbon fiber cloth. But there are obvious market obstacles in the application of products, so it is difficult to compete with other imported products.

3. Application field and future development of CFRP.

With the development of carbon fiber, the application of carbon fiber is more and more extensive, not only in aerospace and other military fields, but also in civil areas. There are many ways to use carbon fiber. One of the most important ways is to weave carbon fiber into carbon fiber cloth which meets all kinds of requirements and specifications, and then use it. Here are some main applications of carbon fiber cloth.

3. 1 Applied to building reinforcement

Carbon fiber (CF) is a new material for strengthening concrete structures in developed countries in the last 10 years. With its excellent mechanical properties, CF is becoming more and more popular in the engineering field. It is called "the new star of structural strengthening". Building reinforcement is also the most widely used field of carbon fiber in China. China is an earthquake-prone country, and the seismic strengthening technology of buildings is an important aspect of research and application in the field of Engineering seismic. Carbon fiber reinforced concrete (CFRP) is widely used in the seismic strengthening of concrete columns. The CFRP bonded structure is a new type of strengthening technology, which has been widely used and has produced great economic benefits.

3.2 Widely used in many fields of civil use.

Carbon fiber prepreg cloth produced by carbon fiber cloth is widely used in fishing gear manufacturing, machinery products, industrial supplies, sports goods, hardware, daily necessities and other fields, but also in the wind power industry, automobile and train industry, sports and leisure equipment, construction industry shipbuilding, automobile and other fields. For example, some enterprises use CFRP to reinforce steel structures, and combined with practical application, they have developed a special adhesive suitable for strengthening and repairing steel structures with CFRP, which broadens the application field of CFRP reinforcement technology.

4. Summary

For a long time, the high price of carbon fiber is an important bottleneck affecting its scale application. But in recent years, with the continuous development of the carbon fiber industry, its price is also gradually decreasing. As the price of carbon fiber continues to be "civilian", its application fields are gradually expanding, the demand will be greater, and the demand for carbon fiber weaving is also increasing.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

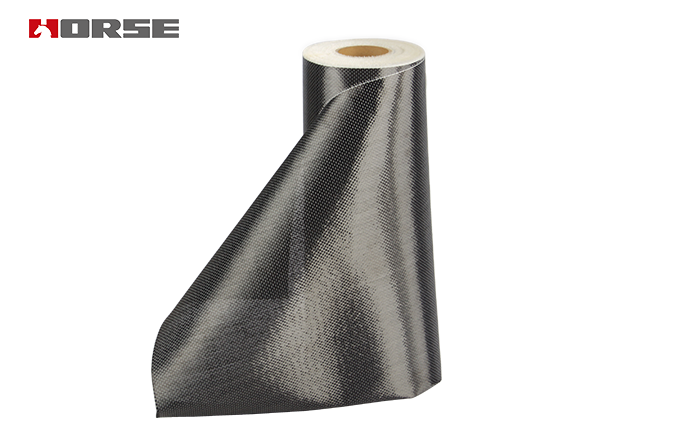

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

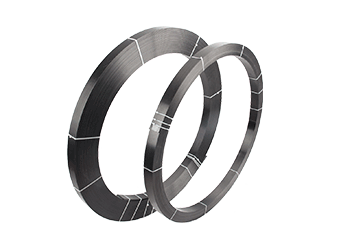

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.