Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fiber materials have been widely applied in various fields of military and civil industry. From aerospace, aviation, automobile, electronics, machinery, chemical, textile and other civil industries to sports equipment and leisure goods.

Carbon fiber (CF) is a new type of fiber material with high strength and high modulus containing more than 95% carbon. It is made of sheet graphite microcrystalline and other organic fibers stacked along the axial direction of the fibers, which are carbonized and graphitized to obtain microcrystalline graphite materials. Carbon fiber is more flexible and rigid than aluminum, but its strength is higher than steel. It has the characteristics of corrosion resistance and high modulus. It is an important material in defense, military and civilian fields. It not only has the inherent characteristics of carbon materials, but also has the softness and machinability of textile fibers. It is a new generation of reinforcing fibers.

Carbon fibers have many excellent properties, such as high axial strength and modulus, low density, high specific property, no creep, ultra-high temperature resistance, good fatigue resistance in non-oxidation environment, between non-metallic and metal specific heat and conductivity, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmission. Good conductive and thermal conductivity, good electromagnetic shielding and so on.

Compared with the traditional glass fiber, the Young's modulus of carbon fiber is more than three times; compared with the Kevlar fiber, the Young's modulus is about two times; it is insoluble in organic solvent, acid and alkali, and its corrosion resistance is outstanding.

Application area

Carbon fiber is an important strategic material for the development of national defense industry and national economy. It is a key technology-intensive material. With the academic research from short fiber carbon fiber to long fiber carbon fiber, the technology and products of using carbon fiber to make heating materials are gradually popularized. Under the background of high-speed industrialization in the world, the use of carbon fiber is becoming more diversified. China has used long fiber as a kind of high-performance fiber, in the high temperature, high physical stability of the occasion, carbon fiber composite materials have irreplaceable advantages. The higher the specific strength of the material, the smaller the dead weight and the higher the specific modulus of the component, the greater the stiffness of the component. It is precisely because of its excellent performance, carbon fiber has a wide range of applications in national defense and civil fields.

Carbon fiber materials have been widely applied in various fields of military and civil industry. From aerospace, aviation, automobile, electronics, machinery, chemical, textile and other civil industries to sports equipment and leisure goods. Carbon fiber reinforced composites can be used in military industries such as aircraft manufacturing, wind turbine blades and other industrial fields, electromagnetic shielding materials, artificial ligaments and other body substitutes, as well as in the manufacture of rocket shells, motor ships, industrial robots, automotive leaf springs and drive shafts, bats and other sports fields. Carbon fiber is a new type of industrial material in the typical high-tech field.

FRP composite material

Carbon fibers are used in traditional use as thermal insulation materials. Most of them are added to resins, metals, ceramics, concrete and other materials as reinforcing materials to form composite materials. Carbon fiber has become the most important reinforcing material for advanced composite materials. Carbon fiber composites have been widely used in aerospace, defense, military and civil industries due to their light and strong, light and rigid, high temperature resistance, corrosion resistance, fatigue resistance, good structural dimension stability, good design and large-area integral molding. Carbon fiber can be processed into fabric, felt, mat, belt, paper and other materials. High performance carbon fiber is the most important reinforcing material for manufacturing advanced composite materials.

Civil Engineering

Civil architecture: Carbon fiber should also be used in industrial and civil buildings, railway and highway bridges, tunnels, chimneys, tower structures and other reinforcement, in railway construction, large-scale roof system and sound insulation wall in the future will have a good application, these will also be carbon fiber has a very promising application. It has the characteristics of low density, high strength, good durability, strong corrosion resistance, acid, alkali and other chemicals corrosion resistance, good flexibility, strong strain capacity. The roof of truss beam frame made of carbon fiber tube is about 50% lighter than that of steel, which makes the large-scale structure reach the practical level, and the construction efficiency and seismic performance are greatly improved. In addition, when CFRP is used to reinforce concrete structure, bolts and rivets need not be added to fix it, so the disturbance to the original concrete structure is small and the construction technology is simple.

Aeronautics and Astronautics

Carbon fiber is an indispensable strategic basic material for advanced weaponry such as rocket, satellite, missile, fighter and ship. The application of carbon fiber composites to missile and engine case of strategic missile can greatly reduce weight and improve missile's range and assault capability. For example, carbon fiber and epoxy resin composites are used in all three-stage shells of intercontinental missile developed in the 1980s. Carbon fiber composites have also been widely used in new generation fighters, such as the fourth generation fighter F22, which uses about 24% carbon fiber composites, so that the fighter has the characteristics of supersonic cruise, over-the-horizon combat, high maneuverability and stealth. Boeing launched a new generation of high-speed wide-body passenger aircraft sonic cruiser, about 60% of the structural components will be made of reinforced carbon fiber plastic composite materials, including wings. The performance of carbon fiber composite brake precast made in China has reached the international level. The carbon and carbon brake discs manufactured by this Prefabrication Technology have been used in military aircraft of key national defense models in batches, and in civil aviation aircraft of B757 type. The use of the carbon and carbon brake discs in other aircraft models is also being tested in experiments, and will be popularized to tanks, high-speed trains, high-class cars, racing cars and so on. Carbon fibers are lighter than aluminum but have similar strength. Carbon fiber also has an important application value in warships. It can reduce the structural weight of warships, increase the payload of warships, thereby improving the ability to transport combat materials. Carbon fiber has no corrosion and rust problem. Because carbon fiber material can significantly reduce structural weight, fuel efficiency can be significantly improved. Aircraft made of carbon fiber and plastic composite materials, as well as spacecraft such as satellites and rockets, have low noise, low power consumption due to small mass, and can save a lot of fuel. It is reported that the reduction of 1kg per spacecraft can reduce the launch vehicle by 500 kilograms.

Carbon fiber is also the perfect material for lightweight modern vehicles such as large civil aircraft, automobiles, high-speed trains. Demand for carbon fiber in aviation applications is increasing, with the new generation of large civil aircraft Airbus A380 and Boeing 787 using about 50% carbon fiber composites. Boeing 777 aircraft uses carbon fiber as structural materials, including horizontal and vertical transverse tails and beams known as important structural materials, so its quality requirements are extremely demanding. The body of the 787 also uses carbon fiber, which makes the plane fly faster, consumes less fuel, increases cabin humidity and makes passengers more comfortable. Airbus is also using a lot of carbon fiber in their aircraft, which will be widely used in the new A380. This has resulted in a 20% reduction in the structural weight of the airframe and a 20% reduction in fuel savings compared with similar aircraft, thus substantially reducing operating costs and reducing carbon dioxide emissions.

Automobile material

Carbon fiber materials have also been a favorite vehicle manufacturer.

It has been widely used in automotive interior and exterior decoration. Carbon fiber as automotive materials, the greatest advantages are light weight, strength, weight is only equivalent to 20% to 30% of steel, but the hardness of steel is more than 10 times. Therefore, the use of carbon fiber materials in automotive manufacturing can make the car lightweight, make breakthroughs, and bring energy-saving social benefits. The industry believes that the use of carbon fiber will increase in the field of automobile manufacturing.

Carbon fibers are lightweight, but they have better safety. Although they look like plastic, they are actually more resistant to impact than steel, especially steering wheels made of carbon fibers, with higher mechanical strength and impact resistance. With the combination of composite materials, the carbon fiber vehicle has become an armored vehicle in family cars. This carbon fiber material has been applied to the skirt of high-speed trains.

Sports goods

Carbon fiber is used in sports and leisure, such as clubs, fishing rods, tennis rackets, badminton rackets, bicycles, ski sticks, skis, sailing masts, sailing hulls and other sports goods are one of the main users of carbon fiber. Carbon fiber is used in daily necessities, such as audio, bathroom, heater and other household appliances, as well as mobile phones, notebook computers and other electronic products can also see the shape of carbon fiber.

The three important applications of sports applications are clubs and racket frames. It is estimated that the annual output of clubs is 34 million pairs. 40% of the world's carbon fiber bats are made of carbon fibers. The world's carbon fiber fishing rod produces about 20 million pairs per year. Tennis racket frames have a market capacity of about 6 million pairs a year, and other sports applications include ice hockey sticks and ski sticks. Carbon fiber is also used in other marine sports such as rowing, rowing, etc.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

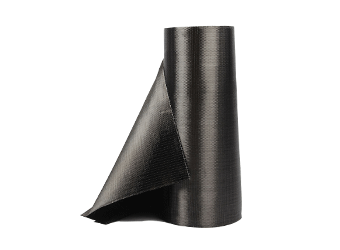

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.